Weldable tungsten tiles improve farm profit margins

10th December 2020

There are a growing number of success stories from using Ferobide weldable tungsten tiles across the UK and worldwide, with the key benefit being better profit margins on-farm, according to UK manufacturer Tenmat.

Arable farming business Gloag & Sons Ltd says it saves two-thirds on wearing metal costs when using Ferobide. Standard cultivator wings now last five times longer when welding Ferobide behind the brazed carbide edge.

Ferobide also contributes to min-till or low-disturbance approaches. Tiles start at only 4mm thick, giving an excellent level of wear performance in such a thin tile, ensuring the perfect balance of tool lifetime and low draft, Tenmat says.

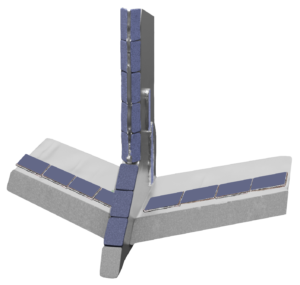

Best used to combat sliding wear, Ferobide is extremely successful used behind traditional brazed tungsten carbide edges, the manufacturer adds. Applications include: behind brazed carbide on wings and points (plough, subsoiler, cultivator), sides of legs (subsoiler, cultivator, seed boots), shins, and scrapers.

Ferobide tiles can now be purchased online, direct from the manufacturer.