Vervaet slurry spreader hits the mark for Somerset-based contractors

1st September 2024

When looking for a self-propelled slurry spreader, the name Vervaet was at the forefront of the search for a contracting company in Shepton Mallet.

The Quad 550 was launched around three years ago and there are already nine working around the UK. With increased demand for greater capacity, the Quad XL was introduced last year and, with two UK sales already, it seems that the Quad and the Quad XL are hitting the right spot with UK farmers and contractors alike.

Farmers Guide caught up with Sion Williams, sales director from J Riley, the sole UK importer of Vervaet, and farmer and contractor Julian Clothier, whose new contracting firm, JJ Agrifert has recently taken delivery of a standard Quad 550, to see how the machine performs in the field.

Sion explained the ethos behind the Quad: “Vervaet’s existing range of three- and five–wheeled machines were not quite right for the UK market, where most of the work is in tramlines; so starting with a clean sheet of paper, Vervaet developed the four-wheeled Quad. Although designed with the UK in mind, the Quad has also found favour with farmers in Germany, Belgium and France.”

The power behind the Quad 550

The 550 in the name refers to its power rating. With a Volvo Penta D13 engine producing 550hp, the Quad is capable of a working speed of 5–15kph using a Vervaet-made hydro-mechanical transmission, with four hydraulic motors, to deliver infinitely variable speed control to mechanical gearboxes, one for each axle, as well as mechanical axles with constant four-wheel drive.

The hydraulic motors can be independently locked temporarily to act as a diff lock, should it be needed. The engine produces a massive 2,650Nm of torque at just 1,200rpm, which helps to keep fuel consumption down.

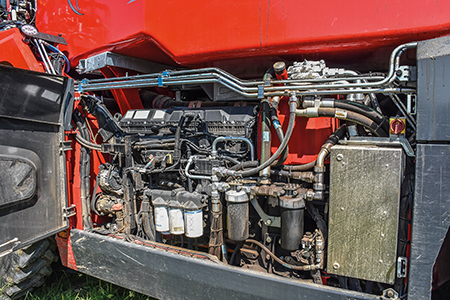

It has a special cooling system that allows it to work at full load in temperatures of up to 45°C. The radiator has been placed at the front of the machine to minimise cooling issues created by dust and crop residue, and it has an auto reverse system to blow out any debris that does find its way into the radiator, and all service items are located on the side of the engine which is easily accessed through the large door.

This same door gives good access to all the hydraulic filters and service parts as well. Volvo Penta also has an excellent dealer network across the UK, so any engine-related service or breakdown requirements should be efficiently dealt with.

Capabilities

Capable of spreading 100,000m3 per year, as long as the infrastructure is in place to bring the digestate to it, the tank holds 22m3 and it can spread at up to 13.5m3 per minute, depending upon the pump specified. The tank is made from polyethylene to help keep the weight down, and it has a slightly tapered shape to allow better visibility of the attached implement and there is also a camera fitted to monitor the centre section.

There is a wide choice of tyre options, all of which keep the Quad within a 3m width, with the standard fit being 900mm x 42 with options of 1,000mm or 1,250 x 42, or 900 x 38.

Wider tyres, good for working on bare land and grassland, spread the weight well, while the taller choices are better for top dressing arable crops as they raise the machine higher. An auto-grease system is included, which leaves only six grease points that require manual greasing.

Filling can be accomplished either via the 10in docking arm from a tanker or slurry lagoon, or via a manual pipe fitting on the front of the Quad.

With a 12,000-litres/min pump on the version Julian was using, filling can be accomplished in just two or three minutes. Within the Claas-made cab, which is pneumatically suspended and air conditioned, the machine had an NIR system from John Deere fitted.

This utilises an infrared system to analyse the digestate for nitrogen, phosphate and potassium, allowing the operator to adjust the flow rate to meet any specific NPK requirements.

There was also a screen showing GPS position and field mapping, as well as the machine’s standard display to provide details about the tank levels, distance to empty, and application rate etc.

The display can also be custom-programmed for the operator’s different implements, so swapping between them becomes as simple as pressing a button. Many other operations are one-touch as well, including filling, emptying and arm docking. This particular model has the well-proven Vervaet macerator fitted, which is good for digestate, but there is an option for a Vogelsang RotaCut, should the slurry be of a more ‘lumpy’ constitution. The stone trap can be emptied from the cab with the press of a single button.

Trailing gear

There are many options for applications tools from the likes of Bomech, Vogelsang, Evers and TBL, but J Riley will work with the farmer or contractor to fit whatever brand of implement that they prefer.

Isobus software is standard for communication with the implement, and this includes section control, if available on the implement, to adjust the working width, or shut off one side, if needed.

A 9t linkage, designed by Vervaet, comes with load sensing hydraulics and also has a pivot so that the attachment can remain square when the Quad is set up in crab mode, with offset front and rear wheels.

Customer opinion

Both based near Shepton Mallet, Somerset, two local farmers and contractors, Julian Clothier and James Bolton joined forces to form the JJ Agrifert partnership – a specialist contractor purely offering slurry application.

This is their first season offering the contracting service, having taken delivery of the Quad 550 in March of 2024.

They exclusively use digestate bought from a local AD plant, and they expect to typically get through around 40,000–50,000m3 per year.

When the business was initially set up towards the end of 2023, Julian and James were considering a couple of options for their machine, including the Quad 550. Explaining what swayed their decision towards the Vervaet, Julian commented: “We really liked the guaranteed value that was being offered after two years. This does, of course, assume a certain number of machine hours and quantity of slurry applied, but it was a large factor in us choosing Vervaet, as it offers a bit of financial peace of mind.

“We also liked that it had a larger capacity than the other machines we were looking at and that it was designed from the ground up as a slurry machine. We chose the dual wheel setup, with twin 380 x 90 on each corner, for working on maize as it allows one maize row to go between the wheels to minimise crop damage.

“We have experienced a couple of teething problems, such as a split pipe, but these are to be expected and they have been sorted promptly. J Riley/Vervaet don’t have a service agent locally, at the moment, but despite this they have fixed the few problems in a timely manner, which is very important when we only have the one machine.

“The way the controls were wired were the opposite way around to my Claas combine, so to make things simpler I got the guys at J Riley to rewire them, which they did with no issues, and now they feel far more intuitive.”

When it came to a rear implement, Julian explained why they ended up with the 24m Bomech trailing shoe: “The Bomech folds up nice and compact for road transport with no additional width, which is important around our local narrow lanes. It can put up to 12kg of pressure onto each element to get the slurry down into the soil.

“This is important as it puts more of the digestate where it needed, reducing costs, and it does a neater job with less plant contamination or problems with scorched leaves.”

Easy filling process

On the day of Farmers Guide’s visit, the Quad, driven by Julian, was being supplied by two tractor/tanker combinations, a Fendt and a Massey Ferguson, and also an artic unit.

Demonstrating the filling process, the articulated filling arm makes docking easy, without needing to move either machine, and filling was quickly carried out with one touch button. “I have added my own camera to the filling arm that allows me to see a little better when docking with the tanker but, more importantly, when I am in the field spreading, I lower the arm in such a way that it points under the front of the Quad towards the front wheel.

“This means that I can see better to line the wheels up with the crop. I also use the arm itself as a guide, for extra assurance. Elsewhere, the visibility is excellent with a combination of rear cameras, the side mirrors and even looking over your shoulder. We have only put around 200 hours on the machine so far, but generally we are very pleased with it. The cab, with its air con, is excellent. You really can’t beat a Claas cab,” Julian commented.

The XL difference

The Quad XL is, for all intents and purposes, a standard Quad 550, but with an additional heavy-duty capacity-enhancing buffer tanker added to the back to cater for those that need the extra slurry capacity or who want to use a 36m boom. The additional tanker has an 18m3 capacity, bringing the total up to an industry-leading 40m3, and has an electronically controlled steering system for accurate tramline tracking and minimal crop damage.

The additional tanker can be removed, and the Quad used on its own, or the tanker can be fitted with its own macerator, pump, manifold and control system to allow it to be used as a towed slurry tank in its own right, offering a good degree of flexibility.

When combined, the additional tank is filled first, followed by the standard tank on the Quad. The additional tank has a small pump that feeds the Quad tank as it empties, so that the slurry is always fed to the implement from the Quad’s computer-controlled tank, to ensure continuity of the programmed requirements.

The extra tanker is fitted with air brakes, which are taken from the Quad. The two sold in the UK so far have both been fitted with a 36m Vogelsang SwingMax dribble bar.

Read more machinery news