‘Revolutionary’ separator has best-selling year

10th December 2020

2020 has been the most successful year to date for the Evolution separator, which in the past 15 years has sold in excess of 650 units to over 30 countries.

Designed by Scotts Precision, this new generation of clod, stone and haulm separator quickly revolutionised what could be expected from damage-free cleaning of virtually all root crops, fruits and alliums, the company says.

A substantial make-over in 2014 saw a host of modi cations, including direct drive motors.

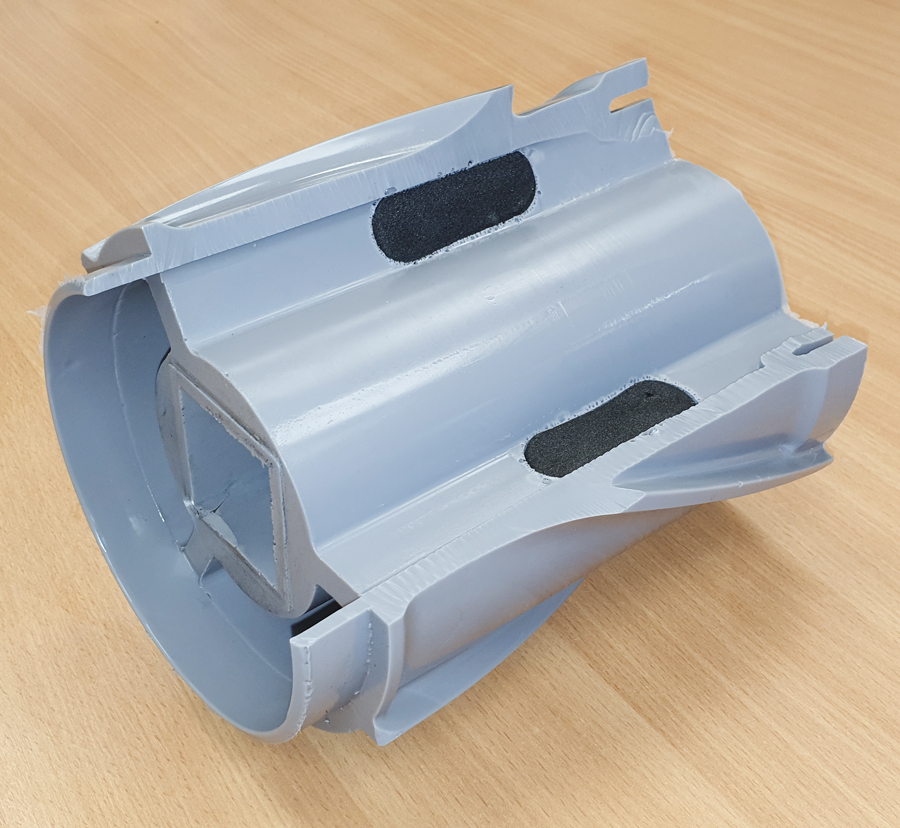

Scotts has control of all aspects of the manufacturing process. In-house 3D CAD modelling, together with 3D printing and CNC machining allow rapid prototyping of spiral roller designs, within days not weeks.

The spiral roller working in tandem with the following clod roller or ‘P roller’ extracts haulm/leaf matter and everything else (clod, stones soil). With haulm, you need to firmly pinch the stems tightly between the rollers to extract them quickly, so a large contact area between the rollers and a stiff rib are key. The Evolution spiral rollers feature a at-topped rib, which has a stiff construction and does not easily deflect away as it ‘pinches’ the haulm against the clod roller.

This eliminates bunging of root balls. There is no need to have the pair of rollers pressed together (causing premature wear), a 1mm gap can be left.

Extracting clod, stones, mud etc relies on the ribs or ‘tread pattern’ to nibble away at the clods; the design of the rib/shape of the valley allows anything that’s an irregular shape to be grabbed by the ribs and pulled down between the rollers. At this point, it’s essential that the tread pattern does not completely ll up with soil and become smooth and the roller itself can deform around harder clods and especially stones.

Scotts features large multiple air chambers that solve these two problems and this is the focus of recent development.

Self-cleaning then is the key and this only happens when two things exist at the same time:

• Regular deformation of the roller body

• Inertia (Scotts recommends 130RPM in wet conditions).

Scotts doesn’t take the simple approach of aligning the air chamber directly underneath the spiralling outer rib, as this dramatically reduces the ‘pinch effect’ and causes bunging.

Instead, it runs its air chambers (and spokes) parallel to the shaft, together with strategically placed foam pockets. This gives varying stiffnesses along each alternate rib to increase the ‘pinch effect’ against the haulm, yet allowing the very best deformation. The inclusion of a foam section also protects the ribs from stone damage.