Optimised drilling at an affordable price

8th March 2022

David Williams visited a Cambridgeshire family’s mixed farm, where strategies to improve soil and crop health, and to reduce costs, have increased profitability.

Farmer Harry Horrell (right) with the farm’s Farmacy agronomist Andrew Buckberry.

Variable rate drilling is just one of many tools in the box when it comes to improving crop performance and farm profitability. However, perceived high costs of investing in the machinery and technology needed can be off-putting. Harry Horrell farms at Thorney, near Peterborough and when he wanted to adjust drilling rates to achieve more even establishment, he converted two old drills rather than buying new.

Trading as C Horrell Ltd, the Horrell family farms approximately 485ha of arable crops, as well as 65ha of grass on which a herd of 130–140 pedigree Shorthorn cattle are grazed. Winter wheat is the main arable crop, along with oilseed rape, spring beans, and hybrid winter rye and maize which are both grown as biomass for a local anaerobic digester.

The land is a mix of owned and some on FBTs in five main blocks and includes a wide range of soil types. “We have areas where the soil ranges from black fen to clay loam within individual fields, and we also have gravel, sandy loam and silty loams,” explained partner Harry Horrell. “We moved from ploughing to a reduced tillage establishment regime, then to direct drilling three years ago.”

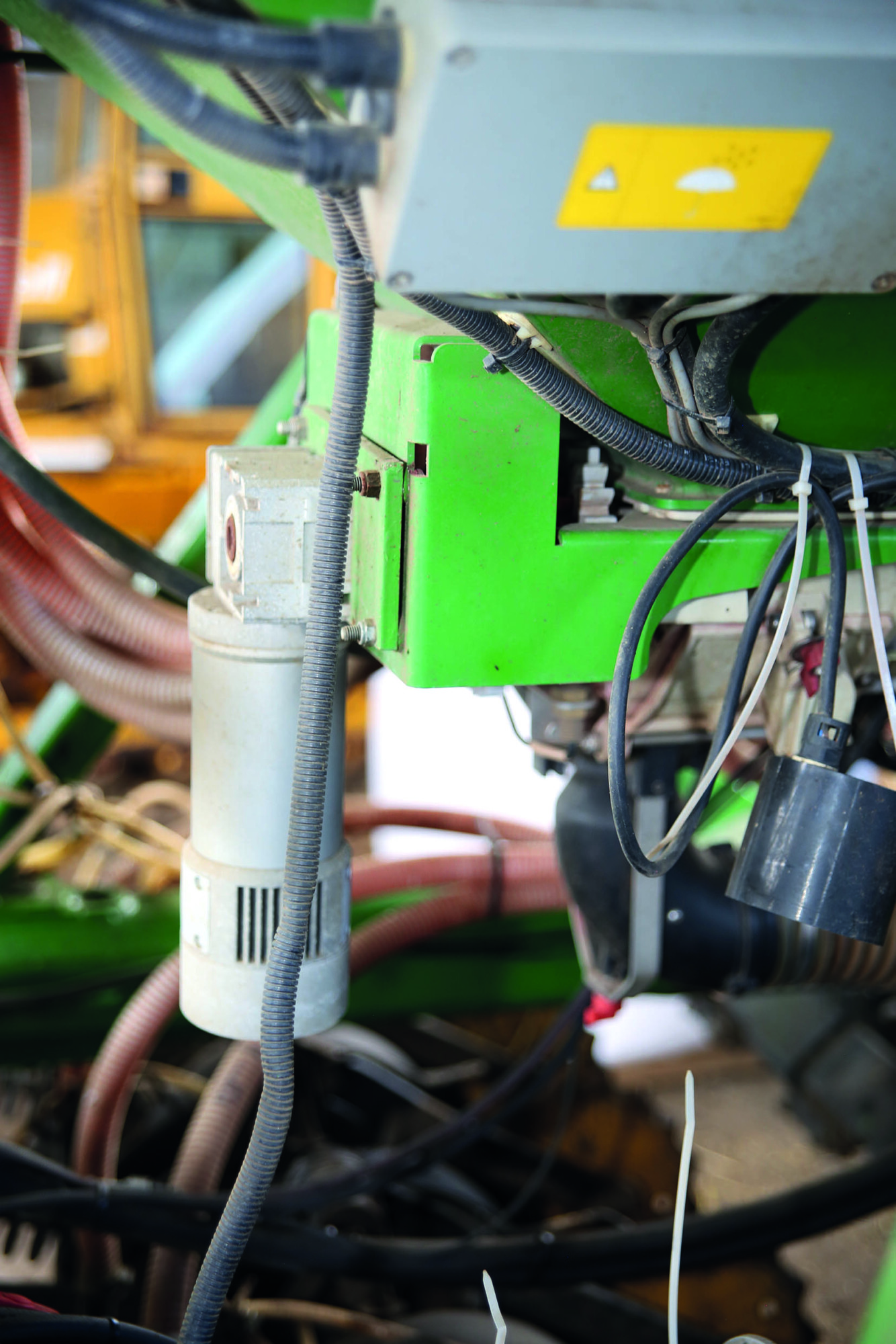

A cost-effective change to targeted seed rates was achieved by fitting the Hutchinsons Omnia E-Seed conversion kit.

Tailored seed rates

Omnia Connect was used to achieve variable rate drilling with the farm’s Vaderstad Rapid drill for several years previously, but the Horsch CO6 drill purchased to work within the reduced tillage regime wasn’t compatible. Reduced soil movement was the priority, so a temporary solution was achieved by a uniform 10% seed rate increase across the farm. However, different soil types achieved different establishment results so crops were uneven, and Harry later moved to a system through which seed rates were chosen to suit cropping blocks, as these each had dominant soil types.

Affordable conversion

Black-grass is a widespread problem in the region and techniques adopted by Harry to tackle it included delaying drilling, but also increasing seed rates in areas of high populations to increase crop competition and stifle the weed. The farm’s drill control box allowed the operator to increase the seed rate by 10% at the touch of a button. This worked, but lacked flexibility and relied on operator accuracy and concentration.

Harry is a Hutchinsons Omnia subscriber, and he worked with the Hutchinsons team to develop an affordable drill control which could also be made available to other farms. A prototype based on existing technology and using a spreader app for control was tested for 12 months, then a dedicated Omnia E-Seed app was created and trialled.

The Omnia E-Seed kit allows any drill with mechanical metering to be adapted for variable rate drilling using the Hutchinsons E-Seed app. An electric motor replaces the standard land-wheel drive, and a WiFi link allows wireless control from an iPad. The E-Seed conversion kit includes the drive motor, fan speed sensor, brackets, wiring and control boxes and is typically fitted on farm in half a day.

Highlighting issues

The farm’s agronomist, Andrew Buckberry of Farmacy, worked with Harry developing the farm’s variable seeding system. Hutchinsons Omnia Precision Agronomy service allows subscribers to use multiple layers of field and crop data to analyse and improve crop performance and this provided the data on which to create the seeding plans.

“When considering variable seed rates, looking at yield maps is a good starting point,” explained Andrew. “These give a general idea and highlight issues such as rabbit or slug damage. High and low yielding areas viewed on field maps usually create shapes, and these frequently tie in with areas where soil types are different. It’s not a full guide, but it highlights areas where issues could be investigated.”

Harry reckons that Omnia provides so many layers of information that deciding on a strategy becomes too complex, so he and Andrew select the most relevant information based on their knowledge of the farm. These include historic yield data, soil type, slug populations, and areas where black-grass is a problem, and a terra map has also been added this year for the first time. The sprayer operator and other members of the farm team have the Omnia Scout app on their phones and they photograph and log anything that they believe might be relevant through the year. The new information is automatically added to the Omnia field data allowing this to be considered when deciding drilling rates too.

“Omnia can analyse it all, but we also apply common sense. In areas of high gravel content, we know that if there is moisture, establishment numbers will be high, for example,” Harry stressed.

High rates effective

Wheat drilling rates start at 400 seeds/m2 and increase to 490 seeds/m2 in areas where black-grass pressure or slug populations are particularly high. Harry said that using high rates is effective, but it’s just one of several strategies needed to fight resistant grass weeds along with delayed drilling and targeted drilling techniques. “We also start harvesting where black-grass populations are lowest in a field, then work away from them to avoid transporting seeds and spreading the problem, and the contractor does the same for us when baling,” he added.

Most of the straw is used for resident livestock, but where black-grass populations are higher the straw is baled and sold for use in a power station to remove the seeds from the farm.

Cover crops

Since moving to direct drilling, the only cultivation is sub-soiling when needed. Cover and catch crops were trialled, but Harry said catch crops planted after oilseed rape have struggled to compete with oilseed rape volunteers, so it was decided to retain these as a cheaper form of ground cover instead. Cover crops have proved more successful. “The main advantage we get from cover crops is the root network,” continued Harry. “But they keep the sun and wind off the soil which means it doesn’t dry out as quickly. When we plant direct into cover crops the soil structure holds together well, and our fertiliser application timings are better as we can get on the land sooner after the winter.”

Successful regime change

Harry said that since moving to direct-drilling, less machinery has been needed and diesel use has reduced by 50%. The farm team is under less time pressure during September which was previously one of the busiest months for cultivations and seedbed preparation. The Horsch drill does most of the late autumn drilling of cereals and cover crops where the Dutch openers create useful tilth, then a more recently purchased John Deere 750A disc drill cuts through mulch to establish the spring crops. The 750A is also preferred for areas where black-grass is an issue for its reduced soil disturbance. Both drills have Omnia E-Seed kits for variable rate seeding.

Farmer Harry Horrell says the Omnia E-Seed kit allows older drills to achieve exactly the same variable rate seeding to new drills and for a fraction of the cost.

Accurate mapping

The entire farm has been accurately mapped including all field boundaries and conservation areas, and RTK guidance is used. Harry said that Omnia has made it easy to create maps for variable rate drilling, and then these are sent to the drill operator for activation. Both drills have identical controls, making it easier for any operator to use either drill. The E-Seed app doesn’t allow tramline creation, but these aren’t needed as RTK guidance ensures that the sprayer and spreader travel on the same ground every year.

“Omnia links easily to Muddy Boots software and all our employees have the Scout app and log any issues they notice while spraying or spreading. It’s about attention to detail to achieve a better result and everyone has a role to play which makes every job more important.”

Savings outweigh costs

“Where we previously increased seed rates for whole fields, now patches where there are known issues such as black-grass or high slug populations are targeted,” explained Andrew. “When we moved to direct drilling we increased seed rates across the farm to compensate, and we succeeded in maintaining yields at previous levels rather than suffering a decline as might have been expected. This was despite unfavourable weather and ground conditions in the first two years. Now yields are climbing as the soil structure improves, and we believe this trend will continue. More is spent on seed now due to the higher rates, but diesel cost savings more than compensate and black-grass populations are reducing too.”

Even cropping

Harry said that moving to direct drilling and variable rate seeding through Omnia E-Seed have both contributed to more even cropping, and particular improvements have been noted on headlands where performance is now similar to the middle of the fields. “Average wheat yields are approximately 10.5–11.0t/ha, but we saw some areas yield 13t/ha last harvest where wheat followed maize that had had a digestate application. Our drilling technique has also changed and where we used to drill headlands first, now they are done at the end. In time we will refine our system further; so that the 750A disc drill does the field centres, and the tined Horsch does the headlands.”

Asked which crops have benefitted most from variable rate drilling, Harry said best results are from winter wheat, followed closely by beans. A crop scanner and Omnia Plant Vision measure and record crop density during all spray and nutrient applications and variable rate fertiliser applications are used. Consistent plant populations and a more even canopy makes crop management easier. Before the change to variable rate drilling, growth regulators were needed every year, but these are rarely used now that highest seed rates are targeted rather than being used across the field.

Practical and affordable

“The Hutchinsons Omnia E-Seed kit is easy to install, simple to use and reliable; and back-up from the Hutchinsons team and especially precision technology manager Oliver Wood has been excellent,” added Harry. “For those using older drills it’s an affordable and accessible route into variable rate seeding. We couldn’t have justified the cost of one new variable rate drill, but have successfully used the kit to convert two older models and gain the same result.”

For more machinery news, visit our website.