The detail behind slurry tanker manufacturing

3rd September 2024

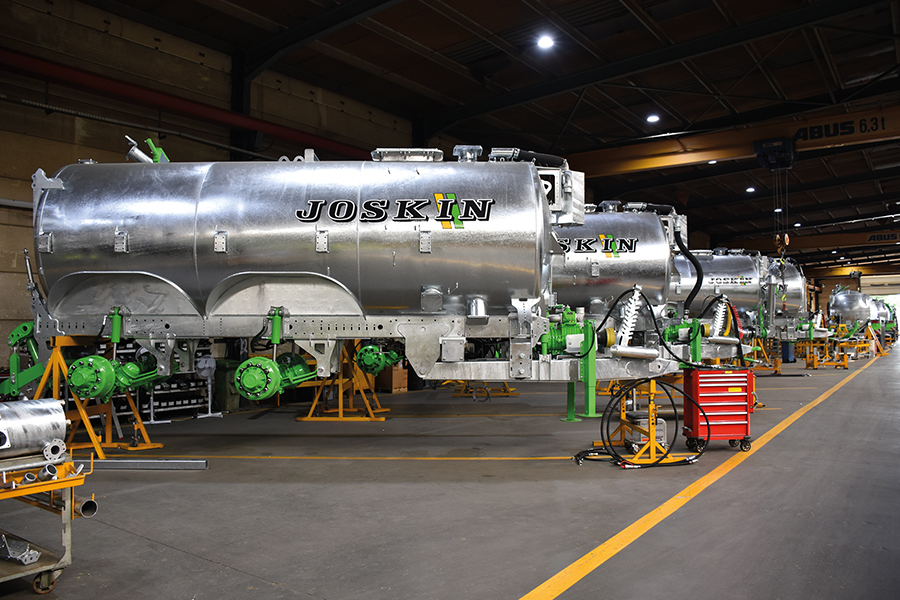

Joskin is a company best known for its galvanised slurry tankers. Farmers Guide took a tour of the Belgium HQ and production facilities.

The Joskin company was started by Victor Joskin in 1968 when, realising that his family farm was too small to sustain the next generation, he set up his own contracting business, which quickly developed a machinery selling and servicing element.

With his wife, Marie-Jose, at his side, the business grew rapidly with new premises set up in the Belgium town of Soumagne, a site where the company’s HQ still sits today. Originally covering just 5,000m2, the Soumagne factory and offices today extends over 17ha, and is just one of five plants owned by Joskin in Belgium, France and Poland.

The early years

In 1974, Joskin started importing and selling machinery, something the business still does to this day, with around 10 different brands in its portfolio. Exactly 40 years ago, in 1984, Joskin started manufacturing its own machinery, with its first slurry tanker, a 3.5m3 vacuum tanker – a product range that it is perhaps still best known for today – followed shortly after by its patented macerator, which is licensed and used on other brands of machine.

At the forefront of slurry injection

With the important Netherlands market right on Joskin’s doorstep, and the early compulsory adoption of slurry injection taken by the geographical neighbours, just four years later Joskin started producing injection equipment, together with its macerator.

Between 1999 and 2012, the company expanded, initially into Poland, to help better reach the eastern European market as well as to be able to dip into an untapped labour force. Then into Bourges, France, followed by further facilities in both Belgium and France – the latter of these being the Leboulch facility obtained when Joskin took the company over in 2013.

Leboulch was a manufacturer of muck spreaders and agricultural trailers and, although now a Joskin site, the name lives on under the Joskin brand with a range of Leboulch-branded tipping trailers and muck spreaders built – mainly for the French market, until now. The Polish factory – the largest in the group – houses Joskin’s state-of-the-art galvanising plant, a very important facility for a company whose output is around 60–65% galvanised.

Back in 2010, the galvanising was all outsourced, but Joskin was struggling to make larger tankers as there were no facilities to galvanise them at that time. The solution was to build its own facility at its Polish site and now everything built in Poland is galvanised there, with 70–80% of the total Joskin galvanised output now carried out in house. Tankers made in Belgium are galvanised in Belgium using a third party.

A large range of products

The Joskin philosophy is to manufacture as much as possible in-house, to ensure the company has the most control over quality as possible. This was obvious as Farmers Guide toured the two factory sites in Belgium, where almost everything from the axles up is produced on site.

The Joskin range encompasses not only its popular slurry tankers, ranging from a 2.5m3, 6t model up to the flagship 30m3, 26t unit, with single, double or triple axles; but also muck spreaders, spreading booms, slurry injectors, various types of agricultural trailers including tipping, silage, bale, grain, multi-purpose and livestock, meadow aerators, pasture toppers and choppers, water bowsers, slurry mixers and hydrocleaners.

Each of the five factories specialises in at least one product, or series, so the staff in each facility are experts on that product range. In Soumagne they make the more complex tankers, like the Volumetra, Cobra or the X-trem, or ones that require lots of electro hydraulics, in Poland they make the simpler Modulo and Alpina tankers and the livestock trailers, and in the Bourges facility in France they specialise in tipping trailers.

Made to order or ‘off the shelf’

When buyers are looking at a potential purchase, they are faced with a huge array of options. While each machine that is customer specified is made to order, and borderline unique, Joskin does not describe them as ‘custom built’.

The customer can only choose from the options available but with, for example, around 900 options on slurry tankers alone, and a choice of around 120 different tyres, it is probably fair to describe them as ‘semi-custom’.

If a customer is looking for a more ‘standard’ machine, Joskin offer the Advantage range across its different machine types. Advantage models are a range of ‘production’ machines with a good, but generic, specification.

The machines are built for stock and the identical nature of them, and the ability to buy parts in bulk, mean the Advantage range delivers a more affordable product at an equally high quality to Joskin’s individual made-to-order machines.

A family business

A tour around the Soumagne HQ starts with the huge indoor showroom, a merchandise shop and a dealer centre offering parts and servicing facilities.

Behind the scenes there are the offices that house all the usual administration facilities required when running an operation of this size, including a translation department that translates relevant documentation into seven languages.

Joskin has around 900 employees across the five sites and Victor Joskin’s three progenies are based there, with specific roles in ensuring the company’s ongoing growth and success. Daughters, Vinciane and Murielle, oversee administration and finance, and HR and communications respectively, while son Didier looks after IT development and production.

Product development

Farmers Guide was given a sneak insight into an area many companies often like to keep under wraps – the development offices where the designers were just wrapping up on the design for a new triple-axle X-trem; a field tanker with around 30,000 litres capacity to compete with the self-propelled tankers. Each part can be developed in 3D and tested with associated parts. They can also be 3D printed if needed.

Farmers Guide was also shown how all the different sites are ‘connected’ using the same computer system and software so, despite being in three different countries, the factories all speak the same ‘language’, whether that is for production, parts, price lists, accounts or any admin functions.

This system allows for full traceability of the 85% of components manufactured in house, as well as the supply of the 15% purchased from outside.

Sales representative, Jean-Marc Vanempten told Farmers Guide: “We don’t see the traditional ‘seasons’ for certain equipment anymore and manufacture slurry tankers and other machines all year round, which means it is important to keep a close eye on parts supply to ensure that there is always a Joskin machine available, if needed.“

Precision manufacturing

In the production facilities Joskin has installed a precision room with a machine that can measure parts, up to 2 x 1 x 1m, in all dimensions up to 1 micron in accuracy. This allows them to produce very accurate parts over and again all within minute tolerances.

The room that houses this machine is kept at a constant 20°C with controlled humidity to remove any inaccuracies created by temperature related expansion and contraction.

A 3D printer and 3D scanner are also housed here to produce prototype parts, as well as some parts used in machines such as their joystick, and to turn existing parts into computerised models. As already mentioned, Joskin produces 85% of all parts in house, and this includes items that require a very high level of machining accuracy such as hydraulic rams, of which they produce most of their own.

Jean-Marc explained: “Details like this are important as, if we buy in hydraulic rams from outside we are beholden to the supplying company to keep on producing the same spec. If they change the design, we may have to redesign our machines. This way we can design a ram to fit our machine and not design our machine to fit someone else’s ram.”

Welding and surface finishing

Although the majority of the welding carried out is done by robots, the parts that make up a typical tanker, or other machine, are usually manually tack welded first using jigs, all made on site, to ensure consistency. To complete the welding on an 8m, 24t, triple axle body would take around three days if it was all carried out manually. The state-of-the-art robot welder can do the same job in just seven hours. The downside is that to programme the robot for a particular body takes a whole week.

Much of the welding in Belgium is carried out at its Spaw Tech site. Spaw Tech is Polish for ‘welding technique’ and this is mainly what happens at this site with bare sheets of steel going in, and complete tankers coming out.

The tanks are produced with sheets rolled into, typically, 2.5m cylindrical pieces, with numerous pieces joined together to create the length. The joints are tack welded manually before being put through a robotic welder to create the seams.

Inside the tanker reinforcement sections are added before the ends are welded on. Interestingly, the end pieces are one of the few components not currently produced onsite, although this is due to change in the near future. Next comes the manual installation of the pre-equipment, brackets, hatches, outlets, manholes, sight gauges and other through-skin components, and the wheel arches cut out on the models that require it. It is then mounted to a cradle or frame.

All tankers are galvanised inside and out. An additional painted surface treatment can be applied as an option, on top of the galvanisation.Other machines are painted or galvanised. Although painted models are usually more cost-effective to produce, and therefore cheaper to buy, it is often the case that customers, who may have been drawn in by the price of a painted unit, will often see the benefits of galvanising and, as such, the output is largely galvanised.

Before surface finishing, all parts are shot blasted using steel balls. Painted components, or machines, are given a coat of epoxy primer followed by a two-component paint application. Galvanised machines are hot dipped in a four-coat process with the first three coats being a mixture of steel and zinc before a final outer coat is applied, which is slightly less hard to absorb the knocks and scrapes.

Running gear

Axles are not produced by Joskin, but as for all other parts coming from other manufacturers, Joskin looks to work with the best product available. This is why the company works with a choice of either ADR or BPW axles on all its machines, and all brake systems have to be checked to meet regulations.

Even the tyres, of which there are many, have to be approved. The tyres are one of the most important, and first, options that need to be picked on a made-to-order machine as the wrong tyre choice, for its intended use, can turn an otherwise good machine into a bad machine. The axles are always bolted on all the machines, to always allow for adjustments and easier maintenance.

Parts and storage

Joskin utilises large ‘rolodex’ style systems to store some of the many parts needed in production. These systems are fully automated and extend to the height of the factory.

All parts are marked with a part number, a QR code and a part description in five languages. All machines come with a unique part list created against their chassis number and that represents all the individual options and components installed, so that even two seemingly identical machines can have slightly different parts lists if, for example, a different pump has been specified. The parts for each machine are picked, labelled with the chassis number and packed onto trolleys ready for assembly.

Production lines

At the Soumagne plant they run two production lines; one for the standard ‘Advantage’ range and the second for the more custom products. The galvanised or painted components are brought together here with the running gear, electronics, hydraulics and all other components to make the complete machine.

Some pre-assembly may have been carried out ‘upstream’ but with all parts identified by chassis number there is complete control of ensuring that the correct components are fitted to the right machine. Once a machine reaches the end of the line, it is put through a thorough inspection. The hydraulics and electrics are tested, and the unit is attached to a tractor for any fine adjustment. When a tanker is finished, it is always tested with water before being cleared. The Joskin philosophy is that when a machine leaves the factory, it should be ‘ready to use’.

Joskin currently exports to around 60 countries around the world and has over 130,000 machine sales to date. The company is not resting on its laurels though; it has a forward-looking philosophy and has other projects, that it is keeping close to its chest, in the pipeline.

Victor Joskin and son Didier are both particularly technically minded and, as such, they ensure that profits are reinvested in modern production tools and facilities to ensure that the business remains competitive and at the leading edge of agricultural machine production into the future.

Read more machinery news