New drill combines high work rates with consistent seed placement

25th July 2024

“We are all trying to get more done with fewer staff, while weather windows get shorter,” explained Forrest Farms farm foreman, Robert Hale.

Forrest Farms in Stowmarket, Suffolk, has been trialling the new Väderstad Inspire S 12m drill this summer, establishing bird feed mix on land owned by the Forrest family and other areas which are looked after under contract farming agreements. The business, managed by James Forrest, includes approximately 1,600ha of arable crops, in three main blocks up to 12 miles apart, and soil types range from chalky boulder clay to sandy clay loams.

The farm started its move away from an entirely plough-based crop establishment system in the early 2000s, and now most of the land is prepared for drilling using one of the farm’s two Väderstad TopDown cultivators, with additional working by a Rexius cultivator press or a Väderstad NZ spring-tine cultivator, but only if needed. The farm’s fleet of three drills includes a Väderstad Rapid 8m, a Väderstad Tempo precision drill for maize and sugar beet, and there is also a power-harrow combination drill which James describes as a ’last resort’ for challenging conditions.

“Like most other growers, we are trying to reduce our operating costs while giving crops the best opportunity to establish in optimum conditions,” stressed Robert Hale. “We farm a large area, so making the most of limited weather windows is essential, but we also look after our soils while aiming for good yields of high-quality produce.”

Influenced farming strategies

The farm relies heavily on Väderstad implements. “Approximately 35 years ago we bought our first Väderstad NZ 6m cultivator which was quickly followed by a Rapid 6m drill,” commented James. “I’ve always been impressed by the amount of research and development that Väderstad puts into its new products, and as the cultivator and drill ranges have evolved and improved they have had a big bearing on how we prepare our land and establish our crops. I don’t believe that there is a better drill than the Rapid, but it’s not available in a 12m version which is why we looked at the Inspire.

“We are always keen to reduce the number of passes and are experimenting with direct drilling oilseed rape with the Tempo, but I still firmly believe that cultivations at an appropriate depth to optimise conditions for crop establishment are the right thing to do.”

Higher output a priority

The 8m Väderstad Rapid drill performs well across the range of soils, but Robert commented that achieving even higher work rates remains an objective. “As soon as I heard about the new 12m Väderstad Inspire when it was announced last autumn, I was keen to trial it, as I believe it is just what we need to achieve even better timeliness,” he continued. “We always prepare proper seedbeds ahead of drilling, so most of the time we just require a seeder that achieves consistent seed depth and effective seed to soil contact at high working speeds, rather than a drill that also moves large amounts of soil.”

Establishing bird feed mix as part of an environmental stewardship programme this summer provided an excellent opportunity to try out a demonstration drill lent by Väderstad UK, just before harvest and ahead of the autumn drilling season.

Väderstad Inspire

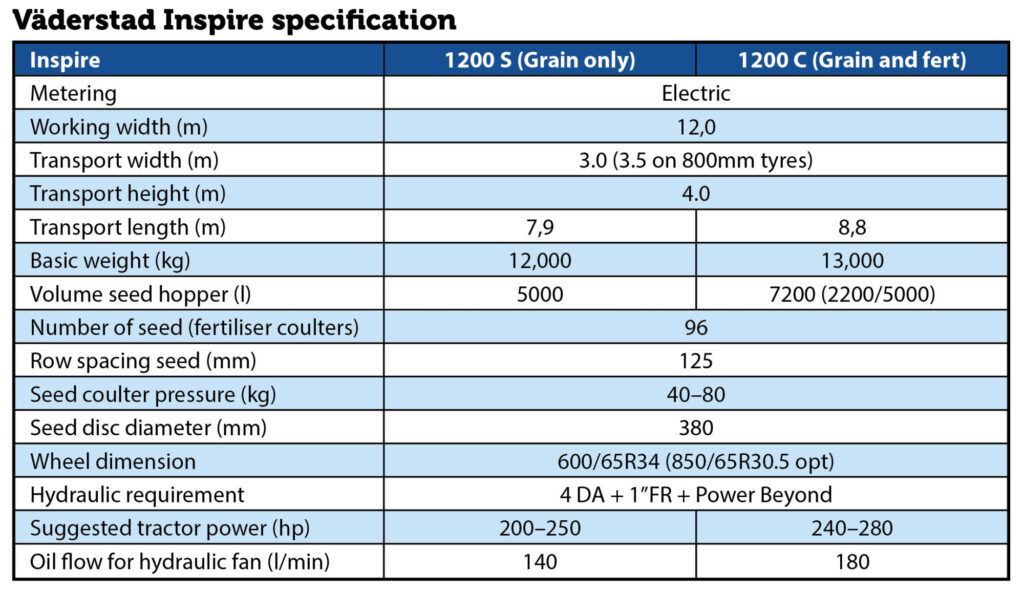

Väderstad UK sales and marketing manager, Andy Gamble told Farmers Guide that the new Inspire drill has already generated significant interest from UK farmers currently using 6–8m competitor-brand drills within conventional and min-till crop establishment regimes, but who want to achieve higher work rates without compromising on results. With no cultivation elements, an additional attraction is that it meets requirements for grant contributions towards the purchase cost.

Choice of front tools

Unlike most other large-width seeders, the Inspire is available with a front levelling board. “It isn’t designed to carry as much soil as the version used on the Rapid, but it breaks up clods and crusts effectively, and levels the surface ahead of the double-disc coulters,” said Robert. “This is one area of the design which I feel could be improved; utilising slightly more aggressive longer kinked tines instead of the straight light standard tines, and I have been told these will be available as an option shortly.”

Proven double-disc coulters

The double-disc coulters feature pairs of 380mm discs with an almost flat profile. The two discs are mounted with a small stagger and at a very shallow working angle which means that the gap between remains constant as they wear. The double-disc coulters are mounted on 96 separate legs, and attached to the frame through Väderstad’s TriForce triangular, three-rubber mounts, which maintain working pressure while allowing a greater range of movement than traditional four-face square rubber mounts.

A hydraulic controlled weight transfer system ensures that working pressure remains equal across the full width of the machine, and allows 40–80kg of downforce to be applied through each coulter to suit the conditions.

Simple design

The shallow-angled pairs of discs create a narrow opening. Seeds are delivered between the front of the discs and the disc axle, and carried down to the base of the slot as the discs revolve. The narrow openings are easily closed and sealed by the following wide press rollers.

The press rollers are followed by a single row of sprung levelling and covering tines, operating between the seed rows.

Accurate and versatile metering

Seeds are supplied through eight Fenix 3 metering units. “They are extremely compact which means there is space for eight of them, below and each side of the hopper,” explained Andy Gamble. “Unique for this drill size, it allows manual or GPS section control in eight, 1.5m sections. SeedEye is an option for seed-only machines, allowing users to specify the number of seeds per square metre required, rather than having to compromise using calibrations based on 1,000-grain weights.”

Väderstad regional aftersales manager, Ian Hale said that SeedEye is proving extremely popular for its ease of use and accuracy, although seed needs to be clean. “Using dirty seed means that SeedEye will count bits of dirt and dust too,” he said.

Massive work capacity

During the extended farm trial, the average drilling speed was 11.5kph giving spot rates of nearly 14ha/hr, although the drill performed equally well at higher speeds up to 14kph. “We have a complete mix of field sizes and many are irregular shaped but, even so, achieving 100ha of drilling per day wouldn’t be difficult for our blocks of cereals,” Robert explained. “Obviously, bigger and more regular shaped fields allow the drill to work more efficiently, but even in much smaller fields you still finish quicker using wider implements.”

Effective depth control

Many wide drills struggle to achieve accurate ground contour following and constant seed depth, but Robert described the Inspire’s performance as exceptional. The tractor’s load-sensing hydraulics respond to feedback from the drill’s ground pressure monitoring system. “I just set the required working pressure on the in-cab display, and the hydraulic management system reacts to keep it constant. It compensates for both lateral and longitudinal ground undulations and everywhere I have checked in the field, the seed depth has been the same.

“With all 96 coulters individually mounted across the four sections, it’s clear that it would cope equally well with uneven land prepared by ploughing too.”

E-Services

The Inspire is Isobus-compliant allowing operation from the tractor controls, and it comes standard with Väderstad E-Services, using an iPad and app to set up, adjust and monitor the implement. Bluetooth connectivity also allows the iPad’s use outside the tractor for convenient calibration and checks. “We are already used to the benefits of SeedEye on our own Rapid drill,” confirmed Robert. “It’s easier to use as well as more accurate, so I wouldn’t want to go back to a conventional calibration system now.”

LED work lights are also standard on the Inspire, on the wings and over the Fenix 3 metering system.

Complements other drills in the line-up

“We offer the Spirit drill in working widths up to 9m, which can be used with or without cultivation elements,” Andy explained. “That is wide enough for most farms, but the new 12m Inspire drill provides the extra productivity that the biggest farms and contractors are looking for.

“Often there is no need for extra cultivation by the drill during planting, especially if seedbeds have already been created. Many farmers do it regardless, but often just because their drill has cultivation elements fitted. The Inspire allows higher working speeds, a lower power requirement and saves fuel, and helps meet the objective of reducing soil movement too.”

Tractor ideal for the task

The 12m drill was pulled by the farm’s Claas Axion 960 Terra Trac. “With up to 445hp available, it has way more power than needed, but we like the front wheel and rear rubber track arrangement for drilling as ground pressure is minimal, and it turns tightly on headlands without creating ridges. Using it partnered with the Inspire drill gives us an opportunity to change the way we work, so instead of doing the fieldwork first and finishing with the headlands, we can start with the headlands and finish in the middle. Even though it’s a very wide drill it’s extremely easy to pull, so the Axion’s fuel use is minimal.”

Verdict

Robert said he is very impressed by the Inspire 1200 S. “The work rate is incredible. During the period we trialled it, the variable weather highlighted the benefits of this sort of drill. With the land pre-cultivated, we had no problem getting the bird feed mix drilled whenever conditions were suitable, and ahead of forecast rain.

“This sort of machine can increase working efficiency, but it can also reduce stress and fatigue during the busy drilling season. We are all used to working long days when required, but being able to complete the drilling in a significantly shorter time reduces the demands on everyone involved,” he confirmed.

Read more machinery news