Claas: “Setting the standard” in forage machinery

1st August 2024

German manufacturer, Claas, unveiled its latest forage technology to the farming press at its factory in Bad Saulgau, southern Germany, at the end of June. Machinery editor Neale Byart reports.

Among the latest products to be unveiled were no fewer than five new Disco large-scale mowers, two swathers, a baler and four tedders.

Claas also took the gathered media on a tour of its factory site and explained how, for the past two years, it has been undergoing extensive restructuring and expansion to increase its production capabilities, and gave an insight into developments within the world of autonomous harvesting.

Disco large-scale mowers

For a quarter of a century, Claas claims to have been setting the standard in large-scale mowers when it comes to area output, durability and efficiency. To mark the anniversary, it has launched five new mower products consisting of four new mower-conditioner combination units and a single XXL mower. This means that Claas now offers a huge range of mower combinations with working widths ranging from 8.3m right up to 10.8m.

Entry level mowers for smaller tractors

The new Disco 8500 C Trend and 8500 RC Trend entry-level models bring some of the tried and tested features of the larger mowers in smaller working widths. This makes them ideally suited for tractors in the lower–mid range, with short wheelbase and power output from 160hp. The focus therefore was on the stable, lightweight construction, with a centre of gravity close to the tractor, and a low rotational and tractive power requirement.

The basic spec includes the proven telescopic arm concept, Active Float ground pressure – adjustable from the cab – and the fast-acting non-stop collision protection that pivots the arm over an obstacle before automatically resetting.

These models can be operated at just 850rpm and incorporate drive protection for each mowing unit, featuring the latest Walterscheid overload clutches. The C model boasts a tine conditioner, while the RC model has a roller conditioner. The latter of these can be fitted with an optional double roller drive with a scissor gear unit.

The conditioner plate incorporates Hardox reinforcement for extra durability while saving weight. Further weight savings have been made by doing away with the LS hydraulic blocks and hydraulic collision protection, which also reduces the purchase price.

High output, lower fuel consumption

The 9.3m Disco 9300 C Comfort and 9300 RC Comfort models are the next step up from the 8500 series and offer many of the same features. In addition, the V-shaped steel tines of the 9300 C model are designed to deliver higher throughputs with reduced fuel consumption.

Suitable for tractors of 180hp and upwards, both models are easy to adjust when it comes to conditioning intensity and deposition width.

The Comfort models can be equipped with optional automatic control of the Active Float system. When working on slopes, the ground pressure – a key factor determining forage quality, sward protection, power requirement and slope safety – can be individually adjusted on each side using the optional automatic slope system. This eases the driver’s workload and, says Claas, ensures consistently high results at all times.

Largest mower has increased working width

The largest model in the Disco range now has a 10.8m working width, up from 10.7m thanks to an increase in the arm’s adjustment range. The working width can also be reduced hydraulically or in synchronisation. Despite its large working width, the whole unit folds to a height of under 4m for road transport. As well as hydraulically controlled lifting, lowering and width adjustment, the unit can also be automatically adjusted using the programmable headland management system.

Faster, efficient baling and wrapping

The Rollant and the Rollant Uniwrap have been popular models of baler and baler-wrapping machines for many years.

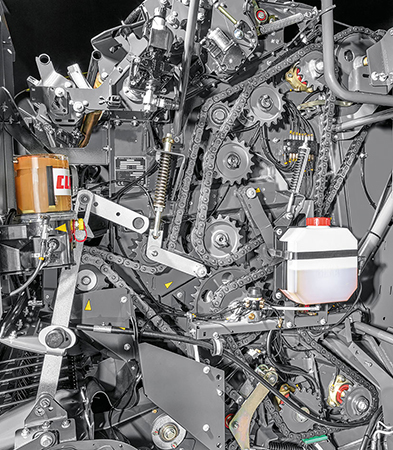

The Rollant 630 RC Uniwrap incorporates much of the tried and tested technology from the previous existing models, but with added features to improve on its design and functionality. It combines good ground clearance with a low centre of gravity and has been strengthened in the important areas such as chassis frame, drive shafts, drive chains and rear tailgate mounting for improved durability.

It also offers a larger chain oil container, now holding 7.2-litres, for reduced maintenance and longer service life. To satisfy the demand for ever increasing bale weights, the frame and tipping cradle have been redesigned to be more stable and to allow adjustable bale diameter from 1.25m to 1.35m.

An optional Maximum Pressure System Plus, or MPS Plus for short, can be added to the Rollant. This pivoting 3-roller segment in the tailgate provides extra pressure to produce better compaction throughout the bale. The pressure supplied is controllable from the cab and can be adjusted between 60 and 120-Bar.

For bale wrapping, the 630 RC can use either net or film and, using technology adopted from the Uniwrap 400, it utilises a hydraulic brake on the wrapping table for reduced film consumption.

The wrapping drive operates at 36rpm, which speeds up the wrapping process, allowing the 630 to add six layers of wrap, with a 52% overlap, to a bale in just 23 seconds. There is also storage for up to 12 replacement rolls of film beneath a large maintenance flap where it is kept both clean and dry.

Swathing with or without a conditioner

Designed for dairy farms that do not need a conditioner because they require longer wilting processes or have less powerful tractors, the Disco 9300 Direct Swather is a large-scale mower offering full-width deposition for fast, effective wilting, integrated central swathing for effective field clearance, 18m mowing width consolidated to 12m swath and mowing with one-sided swath laying for clearing the field margin.

Without the conditioner, the Direct Swather can be operated with tractors from 180hp and is suitable for all crop types and conditions.

The tapered auger is placed close and parallel to the mowing discs to ensure consistent and reliable crop pick-up, even when the growth is uneven. Blockage of the auger outlet is prevented by a shear bar and knives. The top mounted auger drive enables the auger to be swung open hydraulically, allowing the unprocessed crop to be deposited across the full mowing width and can be swung open or closed individually or together via Isobus, even while mowing.

The Disco 9300 C Auto Swather uses a conventional steel tine conditioner to pick up the crop and feed it to the cross-conveyor belt that produces an airy and uniform swath. The resultant swath wilts quickly, even with dense crops and short periods of fair weather.

Manufacturing processes have been optimised for durability, while keeping the weight down, with laser welding and Hardox reinforced components and new drive rollers reduce noise levels for improved operator comfort. It also has a new stand design enabling easier attachment and removal while delivering space-saving storage in the folded position.

The Auto Swather Disco 9300 requires a tractor with an output of 400hp or more but produces a swath of a quality that requires lower power down the harvest chain. As with all Disco mowers, the 9300 models come with a Max Cut mower bed and Active Float suspension, and like all large-scale mowers the side arms have either mechanical or hydraulic non-stop collision protection.

More power and wider working width

The Claas tedder range already covers working widths from 4.5m up to 13m and now, with the launch of four new Volto models, they go all the way up to 15m.

The new models are the 1300T, 1300TS, 1500T and 1500TS. The new 13m and 15m models are available with a self-steering chassis (TS version) or without (T version). All four models feature a new frame and chassis concept, with optimal ground-contour following and soil protection, while offering simple operation and folding.

The new chassis comes with a wide axle and large tyres, to minimise rolling movements and deliver smooth and safe road travel, as well as a compact width, length and height when folded for improved rear visibility and manoeuvring.

They also come with a completely redesigned and stronger Permalink drive that delivers more power for less torque, due to an increase in shaft speed by 50%, and has been engineered for continuous peak performance across the full working width. A redesigned Permalink HD finger clutch and modular, oil filled rotor drives are unique features that set these models apart from others on the market.

All new models feature Max Spread technology with spreader arms angled at 29.3 degrees for optimum spread and a cleaner rake even in damp conditions or in heavy crops.

The 1300 models have 12 x 1.5m rotors and six spreading arms, while the 1500 models have 14 rotors. The spreading angle can be adjusted from 12 to 16 degrees on the rotors without tools and the raking height is adjusted centrally with a crank handle on the chassis frame.

From highly automated to autonomous forage harvesting

Speaking about how Claas defines the future route to autonomy, Magnus Rupp, project manager within the Claas Business Unit for Tractors and Implements broke agricultural development down into three eras: Mechanical, where machinery was developed to replace manual labour; Automation, where driver assistance technology such as Isobus and GPS steering lead on to hands-off co-pilot technology, such as the Claas CEMOS for tractors and combines or Active Float for mowers; and finally, full Autonomy, with the development of machines such as the AgXeed tractor or robotic milking machines, that are completely hands- and eyes-off, and can be operated from a distance.

The use of autonomy within a forage harvesting system does, however, throw up its own challenges, especially in regards to the larger working widths of mowers, tedders and rakes.

Added to this is the fact that grassland fields tend to be more variable in terms of size, contour and inclines, and experience wider environmental conditions. Another consideration is the higher risk of wildlife hiding in the sward.

As part of its path towards full autonomy, Claas is working with various outside partners to help develop features and functions that lay the foundations for full autonomy.

This includes work with companies such as Thermal Drones to develop technology that can identify wildlife, or inanimate objects such as manhole covers, in fields ahead of autonomous mowing so these can be avoided.

In the future, this technology will not only be used on autonomous machines, such as the AgXeed, but also with autonomously driven tractors and harvesters that follow a previously planned route but have a driver and steering system.

Working in the field during the event was an AgXeed AgBot 2.055 W4 paired with a Claas Volto 1300T tedder. “While in practice this is fairly straightforward to prepare, the reality is a little different,” explained Philip Kamps, product manager for AgXeed.

“Thanks to job and lane planning, the use of the tedder is relatively easy to prepare, and the overview of the surroundings is very good thanks to the mown crop. Nevertheless, some work is still needed before the fully autonomous tedder with a large working width can be used commercially on a large scale. For this, the entire area in front of the implement must be secured by sensors.

“To achieve the goal of uncompromising work quality, the complex automation of parameters such as driving speed and rotor speed, as well as monitoring the spread pattern, are also required, which currently does not allow for guaranteed economic use,” adds Magnus.

“Until then, further automated work and functional processes will be incorporated into the forage harvesting chain, thereby easing the burden on the driver, and some of these solutions are already available on the market.” As to when we will see fully autonomous machinery harvesting grass, Magnus suggested this could still be “at least 10 years away”.

Roadmap for the future

With the product portfolio continuously developing and products becoming larger, more complex and more intelligent, the Claas Bad Saulgau production and assembly site has been undergoing a programme of expansion and restructuring over the last two years.

Operating under the codename ForageGO!, the site will see over €50m of investment in plant infrastructure and production facilities by 2025. The improved facilities will include a new 9,500m2 logistics centre, the roof of which will be covered with a 950kWp solar panel array.

The site, which employs around 800 people, is the Claas Group’s centre of excellence for forage harvesting, and the first phase of the project saw the production of Volto tedders and Jaguar crop flow modernised and transferred to a new assembly hall.

Site manager and managing director of Claas Saulgau GmbH, Uli Nickol, explained: “This phase makes a major milestone on our roadmap and lays the foundation for future growth.”

Visit the Claas website for more information

Read more machinery news