Biogas engine upgrade delivers 20% boost in power

5th August 2024

A 500kW biogas plant at Coston Hall Farm in Norfolk recently benefitted from an engine and control panel update from CHP support specialist Gen-C.

The Avocet Renewables’ anaerobic digestion (AD) plant at Coston Hall Farm, Barnham Broom near Norwich, uses agricultural feedstocks such as energy crops to generate biomethane and electricity.

This is exported to the grid, as well as heat, which is used locally on the farm for crop drying.

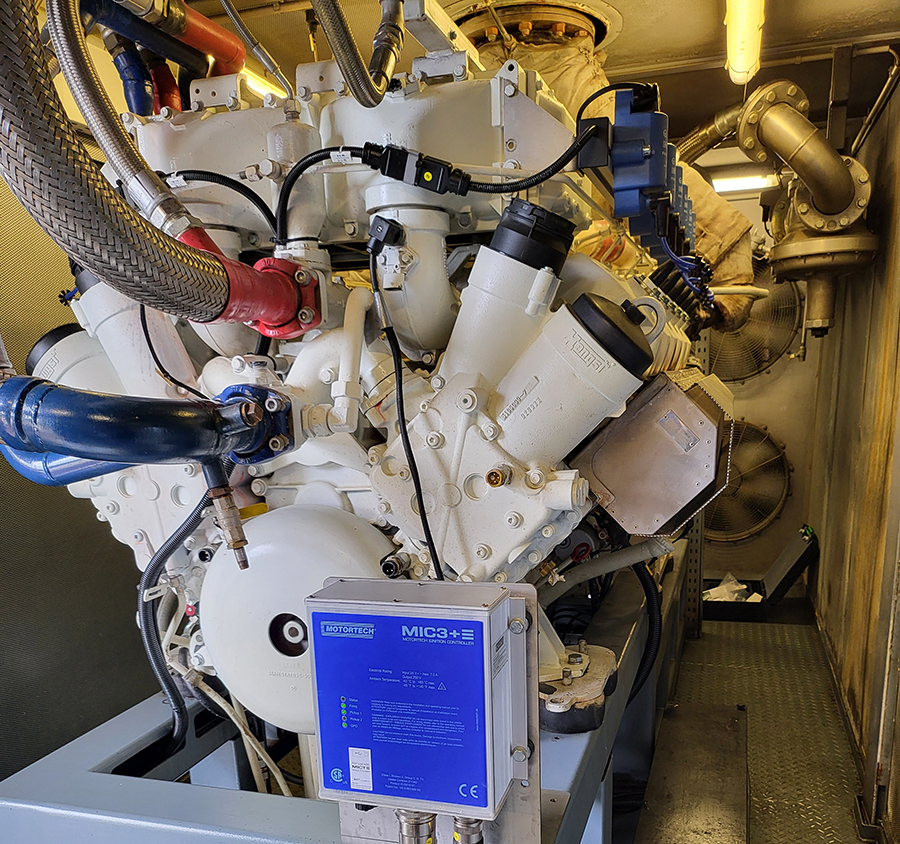

The 500kW V12 MAN E3262 engine was installed in 2017 to provide heat and generate electricity.

Following a technical issue, Peterborough-based GenV Ltd were brought in to service and support the engine.

However, issues such as a locked control panel meant that GenV was limited in its ability to optimise CHP performance, so turned to support partners Gen-C for help.

Limited by legacy controls

“The control system was old, and because it was locked to the original supplier we had no access to change key aspects of how the engine ran, and we couldn’t access anything remotely,” explains Warren Vessey, managing director at GenV.

“After struggling for 18 months with failing engine performance, we performed a full R3 service and agreed with the client to undertake a number of upgrades, including a new open-access control system, with the help of our long-term partner, Gen-C.”

As well as replacing and upgrading the control panel, Yorkshire-based Gen-C was also commissioned to upgrade the engine in a bid to restore lost power output and improve reliability.

“The engine was underperforming – producing only around 400kW – misfiring and vibrating badly, so the client was losing considerable revenue,” says James Thompson, managing director of Gen-C.

“The engine was also comprised of a mixture of equipment from varying brands, which is something we see quite often – the ignition controller, actuator, fuel mixer, pick-ups etc. were from different manufacturers, which was impacting performance.”

Streamlining CHP operation

James continues: “To improve overall performance, we upgraded the key components such as the mixer and throttle speed control.

“And because everything we install comes from one manufacturer (leading German brand Motortech), the client now has a single point of contact for all servicing and spares – as we are the sole Motortech agent for the UK.

“We simultaneously removed the old controllers and screen in the control panel and installed a new touch screen with our controllers and expansion cards.

“The new open-access control system means the AD operator, GenV and ourselves can all access the system remotely and make immediate changes as required, keeping downtime to a minimum.

“The system also features smart diagnostics, with alerts based on user-defined parameters, and is backed by our 12-months free remote technical support.”

Benefits of remote access

The most immediate benefit enjoyed by Avocet Renewables following the engine upgrade is that its CHP is once again running at full power, providing a 20% uplift in output.

With the new components designed to last for at least the next 10 years, the engine is also operating more smoothly which will improve reliability, cut downtime and reduce servicing requirements.

“The open protocol on the new control panel gives us full access to the engine via remote monitoring.

“That means I can see everything that’s happening and can assist the Coston Hall Farm site at any time, from wherever I am, making it far more efficient and easier to use,” stresses Warren Vessey.

“Another big advantage for the client is that they now have full flexibility and choice over who handles their maintenance contract.

“It’s an industry-known system with readily available parts and support, so anyone can access it.

“It’s user friendly and modifications or adjustments can be made from anywhere, which really helps to limit downtime.”

The upgrade was only completed in mid-June, but Mark Gill, plant manager at Coston Hall Farm, is already positive:

“The system works well and is a lot speedier than the old control panel. It’s also much easier to operate and, most importantly, our CHP is operating at full power again.”

For more information, visit the Gen-C website.

Read more machinery news