Are you using your conditioner correctly?

27th January 2022

Mowing with a conditioner enables faster drying and harvesting time, thus ensuring the preservation of nutrients in the forage. SIP provides advice on effective conditioning.

The leaves on the plant dry faster than the stems due to the larger surface and volume ratio and due to the smaller thickness of the epidermis. The stems are designed to move water from the roots to the leaves and this should be done as quickly and as efficiently as possible, without losses of water.

Therefore, stems have a lower surface and volume ratio (i.e. bigger diameter) and are surrounded by a waxy cuticle, which prevents the evaporation of water. Conditioners are designed to damage the stems to the extent that water loss from the stem is faster and the drying time of the stem is shorter.

The two types of conditioners

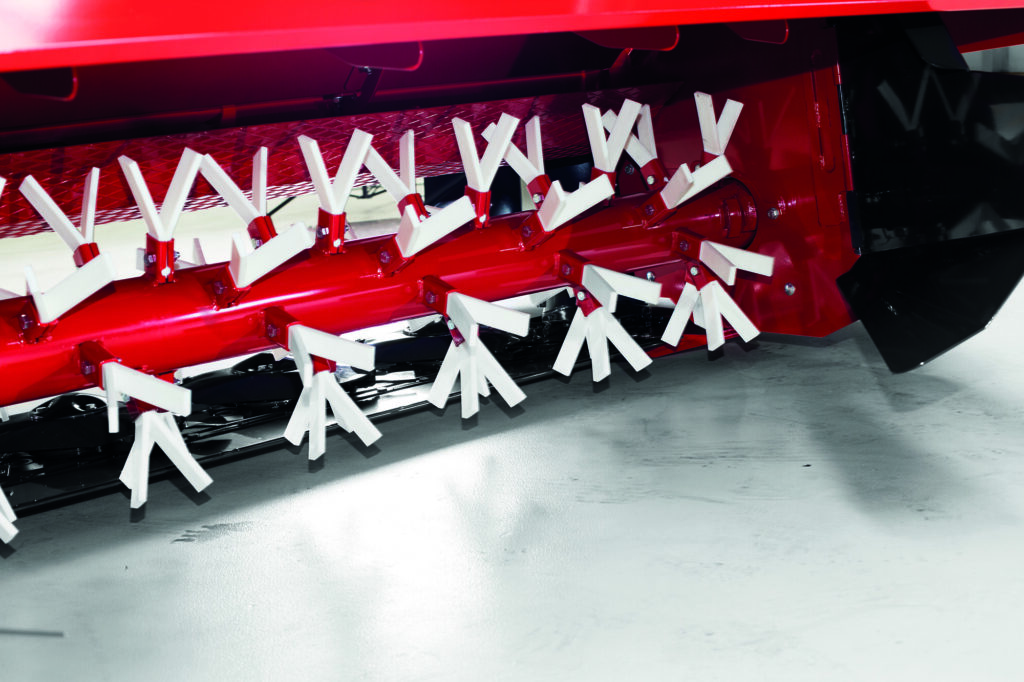

Finger conditioners: On finger conditioners, plastic or metal fingers can be used. They can be movable or rigid, and their function is to damage the waxy cuticle on the stems or leaves, allowing faster moisture loss. The finger conditioner system ensures efficient forage flow, as well as a large airflow through the cutter bar and evenly cut grass. They are recommended for grass stands but not for conditioning clover or alfalfa, because they can damage the delicate leaves and increase the loss of nutrients in the forage.

Roller conditioner: The roller conditioner compresses stems between two rubber or steel rollers, which can be smooth or profiled. The stems are cracked longitudinally and exposed to weather conditions which enable fast water evaporation. This system does not damage the leaves, so they are more suitable for conditioning alfalfa and clover. Roller conditioners, especially steel ones, can be also used to condition grass with a thicker stem such as sorghum or millet, which is common practice in arid areas.

Adjustments for effective conditioning

Proper adjustments to the conditioning system are required for effective conditioning.

When using a finger conditioner, the degree of contact between the conditioner and the forage must be set according to the amount and type of forage. The intensity of conditioning depends on the rotor speed and the distance between the fingers and the deflection shield. When conditioning a larger quantity of forage, the deflection shield should be opened more and vice versa. If the finger conditioner is set correctly all stems should be damaged.

The roller rubber conditioner consists of two profiled rolls with a ‘V’ pattern, which rotate towards each other. The degree of conditioning can be adjusted to the amount of forage by setting the correct spacing and pressing between the rollers.

The working speed of the rollers is regulated by the rotor’s drive system. It is necessary to adjust the correct spacing between the rollers. In case of too much spacing, the forage is not conditioned enough or not at all. In case of too narrow spacing, larger stems cannot get over the conditioner or the leaves are damaged too much. The distance between the rollers must be between 1.5 and 2.3 mm and should be set slightly less than the average stem diameter in the stand.

An equally important setting is the coordinated rotation of the roller. The ribs and slots on the roller must overlap evenly. In this case, incorrect settings can lead to excessive conditioning and loss of leaves. It is also necessary to check the pressure between the rollers, which can be set through the springs. When a yield of dry matter per hectare is low the pressure should be lower and vice versa.

When using a roller conditioner, at least 90% of the stems must be damaged. It is also important that immediately after conditioning the leaves are not coloured black – if they are, the conditioner must be adjusted properly because such leaves dry very quickly, turn white and break on the field. In addition to nutrient losses, incorrect adjustment of the conditioner increases the load on the mower, contributes to faster conditioner wear, and increases energy consumption.

All resources can be viewed here.

For more about conditioners on SIP mowers and for information on other SIP machines, visit www.sip.si and follow www.facebook.com/SIPGreatBritain