Next generation silage inoculants give options to feed recently made silage

6th May 2020

Late turnout and actions by dairy farmers to cut milk output due to coronavirus impact, may see some running out of silage this spring.

Late turnout and actions by dairy farmers to cut milk output due to coronavirus impact, may see some running out of silage this spring. They may be forced to feed first cut much sooner than expected, suggests Corteva Agriscience area sales manager, Jonathan Bellamy.

“It has been a very long, wet winter and many cattle have been indoors longer than usual,” says Mr. Bellamy. “And farmers hit by a drop in demand for milk, will probably cut down on expensive concentrates and rely more on conserved feed. This means they will get through last year’s silage much quicker than expected, and could even be opening up first cuts to feed before second cut is harvested.

“If this is the case, we are recommending farmers apply the Rapid React versions of our silage inoculants. This will ensure not only excellent fermentation, but also aerobic stability that is achieved in as little as seven days after ensiling.

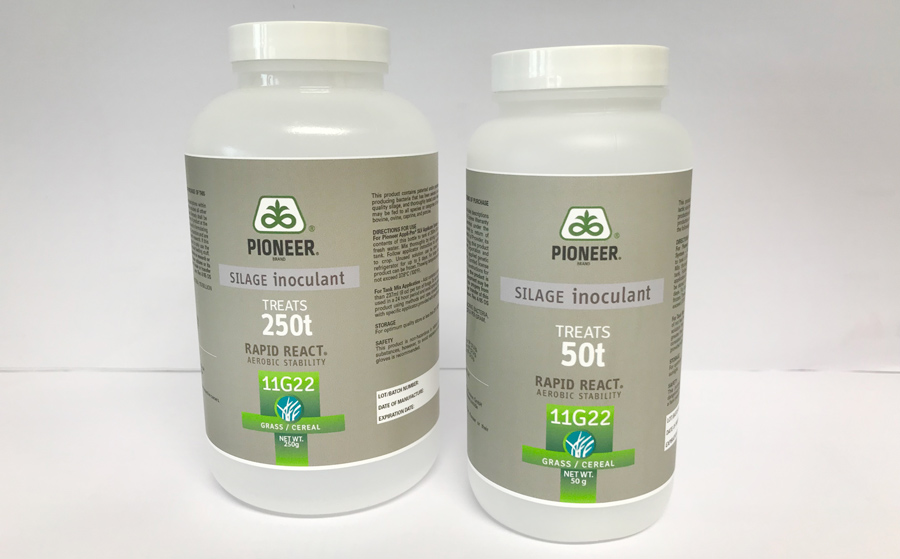

“Pioneer brand 11G22RR for grass silage, contains a combination of patented and proprietary strains of Lactobacillus buchneri and Lactobacillus plantarum, with the Rapid React strain able to produce aerobically stable silage much quicker than formulations without it.”

Peter Clayton runs a flying herd of 320 commercial Holstein x Friesians at Larkton Hall in Malpas, south Cheshire, yielding an average of 8,600 litres with 4,200 litres coming from forage, with 4.7% butterfat and 3.27% protein.

He has been carrying out a multi-cut silage programme for some years and uses Pioneer inoculants. Last year he tried 11G22RR for the first time and was ‘blown away’ by the results.

“I had never seen anything work like 11G22RR – we instantly felt it was very different to anything we had used before,” says Mr. Clayton. “There was a good fermented silage smell almost straight away and no heating whatsoever. I am always very aware of heating, because that loss of energy is energy you want inside the cows, not wasted.

“We used it on all cuts last year, but third cut was notable. After we had finished harvesting, we left the face unsheeted and went back and started feeding it three days later. It was fully fermented, there was no heating and it fed very well. (Table 1).

“Rapid React ‘does what it says on the tin’ and I am certain I get enhanced performance from using it. I shall be treating all cuts with 11G22RR this year.”

Table 1: Silage analysis for Larkton Hall 2019

| First cut | Second cut | Third cut | |

| D Value | 65 | 63 | 64 |

| Crude protein (%) | 13.7 | 17.0 | 12.5 |

| ME (MJ) | 10.4 | 10.1 | 10.2 |

| pH | 4.3 | 4.9 | 4.6 |

Paul Hutchinson milks 120 all-year-round calving Holstein cows through two robots at Whitwell Grange near Richmond in North Yorkshire. The cows yield an average of 10,000 litres a year.

They are fed cake through out-of-parlour feeders linked to the robots, supplemented with silage topped with a moist co-product feed.

Paul used Pioneer Rapid React for the first time last year when he was falling short of conserved forage after the summer drought in 2018.

“Applying an additive that means the clamp can be opened up and fed within a couple of days was very attractive to me last spring,” Mr. Hutchinson explains.

“First cut on 20 May was a little late, but it was easy to apply, and we were feeding it a few days after ensiling. The silage was cold and there was no waste on top. The analysis came back at 70 D value, 16% crude protein and 11 MJ ME. The cows loved it and daily milk yields jumped up a couple of litres to 34, at 4.24 butterfat and 3.4 protein.

“We are going to run out of silage again this year, as the wet autumn meant we didn’t take a fourth cut.

“We have bought a forage wagon so we can harvest the grass at exactly the right time and will be using 11G22RR on all cuts. It is critical that we have the best forage quality, so the cows can milk as well as possible and we can make more money.”

11G22RR is available as a water-soluble product in packaging suitable for use in tank mixes or with the Pioneer Appli-Pro system for easy and convenient application.