Dairy, Forage & Silage

10th March 2020

Dairy, Forage & Silage Feature from our March 2020 Issue

Silage quality and increased flexibility result from new harvester investment

Three years ago, Cheshire-based dairy farmers AL Moore & Partners replaced their trailed forage harvester with a new self-propelled model, with the aim of optimising forage quality. David Williams visited the farm to find out if the decision has proved worthwhile.

The farm is run by Alan and Stephen Moore, and the herd consists of approximately 550 pedigree Holstein cattle on two sites a few miles apart. Cattle are outdoor grazed through the summer with supplementary feeding of a TMR including maize and grass silage. With seasons changing, and weather windows for making good quality silage becoming shorter and less frequent, the farm’s tractor-powered trailed harvester was replaced by a new Claas Jaguar 840 self-propelled. “Making good silage is key to maintaining good year-round milk production and catching the grass at exactly the right time is critical,” emphasised Alan. “If we can produce good silage then the cows remain healthier and perform better.”

Invest or use a contractor?

“We had operated trailed harvesters for the past 30 years, but felt we needed to speed the job up,” continued Stephen. “We had two options – invest in a self-propelled or use a contractor. We get on well with the local contractors and use them for our maize harvesting, but because there is such a short period when conditions are ideal for grass harvesting we wanted to maintain full control – being able to harvest when we wanted to, and not be under pressure to continue cutting if conditions weren’t suitable. My son William is keen to join us on the farm and we see a positive future for the dairy industry, so we are always prepared to invest for the future and started looking for a suitable self-propelled machine.”

Several brands were considered, but Claas was an early favourite for its strong reputation and back-up available from Morris Corfield, the local dealer. The family already operated a Claas rear-mounted mower and a rake which were preferred for their performance and build quality, compared to other brands which they had tried.

A Claas Jaguar 800-series harvester was identified as being the ideal size, and the search began for a suitable used model. “Most were from contractors so had worked a large number of hours, as well as having features that we didn’t need,” Stephen said. ”And, with demand high for used Claas Jaguars, it seemed that as soon as we heard of anything suitable it had already been sold. We knew that with the area of grass we cut annually the hours would remain very low and we would keep it for many years, so with a relatively small price difference between a good used machine and a brand new one built to our ideal specification, we placed an order.”

The Jaguar 840 was purchased from Morris Corfield with a Claas 300 grass pick-up. The Claas Liner grass rake was also upgraded to provide a suitable swath for the new harvester. For maize harvesting, the family decided to continue using the services of a contractor, partly because it was hard to justify the additional cost of a maize header and cracker for the relatively small area of crop.

Saving time, gaining flexibility

Stephen said investing in the Jaguar has proved worthwhile – saving time and adding flexibility. “It allows us to be independent. We can harvest when we want and take time away from the field for other tasks when needed. It also provides added opportunities to take extra cuts when grass growth might not justify bringing in a contractor. When a good spell of weather arrives, everyone is on to the contractors wanting their harvesting done, but we don’t have to worry, so the harvesting season has become easier. Chop quality is much better than we achieved with our trailed machine and the silage has improved as a result.”

Easy to use

The main operator is Glyn Tucker. “We had several harvesters on demonstration, but I preferred the Claas,” he said. “I very much enjoy using it – it’s easy to drive and very comfortable. The dealer arranged a useful one-day training course which taught me the basics, and it took little time to get used to it. It’s much easier to use than the trailed machine, with chop length adjusted at the touch of the screen in the cab whereas we used to have to leave the tractor cab, select the appropriate gear according to the conditions, and then get back into the cab. The Jaguar has plenty of power to cope with variable crops and I average approximately 4ha of first cut harvesting per hour. The visibility from the cab is excellent. Using the trailed machine, I had to look back over my shoulder at the pick-up all day. The Jaguar is so much more comfortable and features such as the chute camera make it easy to keep an eye on the trailer while watching the pick-up. When we are under pressure to get the grass harvesting finished I sometimes spend 12–14 hours in the seat and cut at night, but the excellent cab and controls mean

it isn’t too tiring.”

Successful move

So far, the Jaguar has proved trouble-free and just as reliable as the farm had hoped. Glyn said routine maintenance is straightforward and that auto-lube looks after most grease points. “The blade sharpening is fully automatic too, and the machine even tells me when sharpening is needed. Getting at the blades of our trailed machine for sharpening was difficult and required several hours,” he added.

“On our size of farm, the benefits we gain from owning the machine mean it is easily justified,” concluded Stephen. “Margins are under pressure and using a contractor for the grass as well as the maize would add a lot to our costs. Having invested in the new Jaguar, which won’t work many hours a year, we will maintain it well, keep it in good condition and expect it to hold its value while remaining on the farm for at least 20 years.

Six steps for sward success

Forage grass experts discuss a plan of action for getting your fields back to full fitness after a wet, mild winter.

The UK has experienced unseasonably mild conditions this winter, with temperatures over 1ºC higher than the long-term average. Combined with high rainfall, this has resulted in extensive flooding and waterlogging and a dramatic impact on grassland. Soil in many places has become compacted by the weight of water lying on it and valuable nutrients have also been lost to leaching.

Grass seed producer Barenbrug UK has produced a list of actions for getting swards back in shape.

Make a forage plan. Work out your farm’s forage requirement for the year to allow for effective grassland management planning.

Walk your fields. As soon as conditions allow, complete a visual assessment of your field/s. Those that need most attention will be easy to spot. If pastures look an unhealthy shade of yellowy green, that’s a clear indicator of stress. Patchy areas of growth are also a definite sign of compaction and poor soil structure. Record information in the Good Grass Guide.

Dig deep. Dig a pit to around 30cm or the depth of any pan to assess the extent of damage. If the grass roots aren’t penetrating below 10cm then you are dealing with a clear case of compaction. Another sign is if the soil is bone dry from 7–15cm down. Compaction can drastically affect the growth rate and rooting structure of newly sown grasses – reducing productivity by 10–20 per cent. It can also prevent the uptake of nutrients, restrict drainage and ultimately cut down on the number of working days you’ll get from a field.

Soil sample. Maintaining grassland soils at a pH of at least 6.2 and P&K at index 2 is fundamental to successful grassland productivity. High levels of water, like we’ve seen this winter, can drastically affect pH and the more acidic the soil, the greater the chance of lock up, making vital nutrients unavailable to plants. Invest in a broad-spectrum analysis, not just a basic sample, to give a better picture of the trace element balance (paying particular attention to the calcium to magnesium balance) and allow for better liming and fertiliser choices.

Correct any issues. By leaving problems unrectified, production, soil health and profitability will only decline further.

Sward rejuvenation or replacement. Once soil structure and fertility issues have been addressed, new leys can be drilled into place or overseeding can occur. If the aim is to get grass producing quickly then it’s best to overseed with a mix of fast-growing vigorous tetraploid ryegrass species. These will start delivering results after 6–8 weeks of establishment – improving ground cover and giving a real spring boost to yield and quality. But remember, overseeding is only a short-term solution. For longer-term results on problem pastures it is advisable to replace the grass with a more suitable ley come the autumn.

Retrofit low emission slurry spreader

Major Equipment has launched a dribble bar and trailing shoe slurry spreader to help farmers maximise the benefit of slurries and ensure compliance with environmental regulations. Both units have a 7.5m working width and can be retro-fitted to any tanker make or model.

The units are designed to apply slurry to the soil surface as accurately as possible, while minimising grass contamination and ammonia emissions. Both have 30 outlets, spaced 260mm apart for even and precise distribution of liquid material in long and short grass.

They are easily mounted onto the back door without welding or fabricating. Brackets with settings in 60mm increments allow either unit to be set according to the tanker height, making the system adaptable to any tanker make or model. They can also be used with the existing splashplate left in place.

When arms are folded and locked into place, the trailing shoe and dribble bar have a transport width of 2.4m and 2.2m respectively. For safe and legal road use, a full lighting board is fitted as standard. There is a double self-aligning pivot hinge with easy access grease point on each wing for increased durability.

Both units are made from high-strength steel and galvanised to increase durability and lifespan. A Vogelsang ExaCut macerator is centred on both units to deliver optimal cutting results and eliminate blockages.

Turning attention to grassland management

As we go into spring after a very difficult autumn – and with grassland management at the forefront of farming trends – the Guttler Greenmaster 640 system should be a consideration for livestock farmers, arable farmers and contractors alike, according to Wox Agri Services.

The Greenmaster 640 Harroflex element has all the features of the very popular Greenmaster 300, the company says. This includes the patented ripper board tine and fully adjustable 12mm sprung tines suitable for coping with all the variable conditions faced when working with grass swards from plough-based to non-inversion situations.

The Master 640 trailed rollers – with the classic Guttler Prisma rings (designed to mimic the sheep’s ‘hoof’ effect) – ensure effective seed-to-soil contact for all seeds placed by the system. With a seeder unit that is able to cope with small seed crops, from clovers and OSR, up to grains, stubble turnips and specialist grass seed mixes, the Guttler Greenmaster System can provide the answers to a never-ending, complicated farming conundrum, Wox Agri says.

Working closely with seed suppliers and agronomists, the company advises farmers to ensure they are ready when the conditions are. The Guttler Greenmaster 300 and 640 systems are available ex-stock from Wox Agri.

New maize dry matter monitoring tool

A new online tool developed by KWS will allow maize growers to use satellite imagery to view their own fields, in order to improve the assessment of harvest readiness.

Due to go live in 2021, the precision management service has received excellent feedback from farmers who took part in the 2019 pilot study and additional participants are being sought for this season.

The KWS DM Monitoring Tool uses satellite imagery alongside information on the FAO, or maturity rating, of a variety combined with real-time data on rainfall, heat units and radiation on individual farms. Accurate to 10sq. m, the colour coding system indicates whether the crop is too wet, harvest-ready or if DM content has exceeded optimum figures.

Making a decision on maize cutting dates can be challenging and it is estimated that up to 50 per cent of fields are not harvested at the correct time, with a negative effect on crop quantity and quality, says KWS’ John Burgess.

“Maize growers have become sophisticated in their ability to determine dry matter levels in individual plants, but there can be a wide variation within each field. This can present difficulties, when it comes to making a decision on harvest dates.

“The internet-based service will increase the accuracy of decision-making, compared with the standard visual method. It has the potential to be particularly useful for growers with large acreages, as it will help them to prioritise those fields which are ready to cut.

“It will also help to pinpoint cutting dates on smaller farms and it is anticipated that it will improve yields and quality across the national maize acreage, as well as reducing the potential for silage losses,” he says.

The aim is for the system to cover some 80 per cent of the UK maize acreage by the end of next year. It will cover 10 European countries.

If you are interested in joining the pilot study, contact John Burgess on 07766 258264 or email Alison Phipps via alison.phipps@kws.com.

Keops – top KWS maize variety for 2020

Keops has heavy yield potential and a wide drilling window, making it an ideal choice for silage or AD in warmer areas, reports Mr Burgess. It falls into the early/maincrop category and has an FAO of 210/220.

“Keops has a tremendous yield figure of 50-55 freshweight tonnes per hectare, along with a high grain/stover ratio, which offers stable ripening in cooler seasons,” he says. “Another trait is its rapid early vigour. Getting the crop off to a good start is vital for maximising both yield and quality potential.

“I would strongly recommend the inclusion of some of the newer maize varieties in the farm portfolio for this year. As plant breeders, we have made huge strides in terms of genetic progress over the past few years on a wide range of economic traits and there is an opportunity to take advantage of some of the more recent advances.”

Baling crops with precise knowledge

Whether baling silage, haylage, hay or straw, understanding the conditions is vital. Aiming to lead the way in forage management equipment, Profitable Farming Company offers precision moisture sensors for all balers, with systems either fully integrated or smart device controlled. For large and small square balers, precision star-wheels measuring up to 70 per cent moisture are used, while twin disc technology for round balers offers up to 60 per cent moisture readings, with accuracy at +/-1 per cent. The system measures throughout the bale – pulsing from side-to-side and giving up to nine readings per second to gauge the overall moisture level.

Once the accurate moisture level has been obtained, there are then options to manage the bale quality. Utilising the wet bale marker will identify bales which exceed the safe moisture baling limit and allow separation in the stack.

According to PFC, using its baler-safe buffered acid preservative will extend the baling window in hay and straw by up to 30 per cent. The application systems will monitor the baler performance and crop moisture, and adjust the application rate automatically every second. Declared by the company to be the strongest preservative on the market for hay and straw, it has a pH of 6.0, making it baler-safe and suitable for all livestock, including horses.

Using market-leading application equipment and preservative will improve efficiency and forage quality, while reducing production costs.

The right attachment holds ‘key to quality clamped forage’

Clamping silage has been seen to be a bottleneck in the green harvest process, manufacturer Albutt says, so the right attachment is needed to produce quality clamped forage and boost productivity of clamp loading machines.

Production of the company’s buck rakes and folding forks has seen more than 5,000 units leave its manufacturing facility for destinations around the globe. Its buck rake model line-up covers four widths, from 8–12ft, and there is a choice of either Hardox or forged tines.

Folding forks are gaining in popularity as wheeled loader sales increase in agriculture, the company adds. Its range offers capacities from 6.9–9.4m³. According to Albutt, the high capacities offer great payload and fast clamping speeds, improving productivity of the clamp operation. Hydraulic folding wings allow the fork width to be reduced to 3m to allow rolling up to the clamp wall, maintaining feed quality across the full width of the clamp. This improves clamping productivity and increases time for clamp rolling, eliminating air pockets and improving feed quality. Albutt also offers accessories including LED work lights and tine guards for both product ranges.

The range will be on show at Grassland and Muck on 20–21st May.

Wide range of options for diet feeders

Hi-Spec Engineering Co Ltd outlines its selection of diet feeders, which it says can offer one of the widest ranges of feed-out options of any machine on the market.

The Hi-Spec vertical auger range of feeders is available in both single and twin auger variants and sizes from 7–32m³. It can incorporate complete bales into the mix quickly and efficiently due to the unique knife arrangement, which also allows the vertical auger mixer to be used with lower horsepower tractors. The range uses a low pitch mixing and chopping auger that creates a simple cycle action and is fitted with eight self-sharpening knives, one of which runs close to the body of the vertical feeder. This ensures that, once the mix is drawn up by the auger, as it falls back down the side it continues to be chopped and mixed, so a quick and thorough mix can be achieved consistently.

Options include various discharge outlet positions or a variable height hydraulic chute or cross conveyor with elevator. It can also be specified with the Digi-Star TMR Tracker fully programmable electronic weighing system. The vertical auger can be fitted with a straw blower, so it can also be used as a bedder, or with a root washer and cleaner so root crops can be incorporated into the mix.

The company says its MixMax range of paddle-type feeders are designed to be flexible, sturdy and economical, with a long-lasting and simple design that ensures low running costs and low maintenance. The Hi-Spec Feed-Flo mixing system features single-angled rotor arms to provide thorough end-to-end mixing and a light fluffy ration, without the need for multiple augers. The mix is discharged through a hydraulically operated door, through a teaser roller that makes it easy to adjust the flow rate and provide an even, consistent feed-out.

A total of seven single- and double-axle MixMax models are available, ranging from 10–24m³. Options available include the Digi-Star Tracker programmable weighing system, a hydraulic or fold-down elevator and the root washer and Chopper for incorporating root crops into the ration.

New research indicates more milk from quality forage

At an industry briefing in mid-February, the findings of two new research projects were presented, which suggest significant increases in grass energy yield/ha – and the subsequent improved milk from forage potentiality.

Analysing data from different dairy systems, SRUC professor of dairy nutrition John Newbold, outlined how maximising milk from forage is positive for bottom line profitability, whatever the production system. He commented that not only was feed the biggest business cost, moreover the most profitable 25 per cent of farms were the ones that produced more milk from forage – whether grazed grass, silage or a combination. His advice for profitability was to grow better grass, make higher quality silage and to use the silage more effectively.

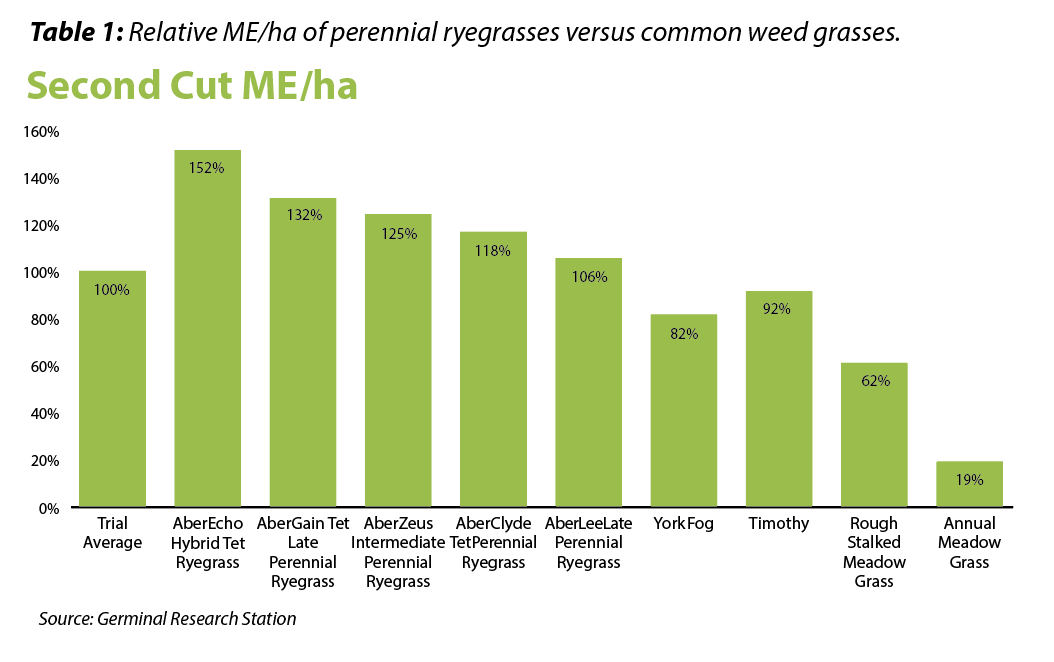

In terms of growing better grass, Germinal GB’s Ben Wixey discussed a new study underway at the Germinal Research Station, where the metabolisable energy (ME) yield/ha value of perennial ryegrasses is being compared with the energy potential from weed grasses that predominate in deteriorating swards.

“Grass leys do deteriorate with age, which means lower-value weed species replace the perennial ryegrasses that were selected and sown at the time of reseeding,” he said.

“…We’ve calculated that a new reseed would potentially contribute around 2,000-litres/ha more milk from forage than a five-year-old ley with just half of the perennial ryegrass remaining. If we extend the life of the old ley to 10 years, with just 25 per cent perennial ryegrass remaining, then the difference rises to 3,410-litres/ha (See Table 1). If we apply a milk price of 27p/litre, this roughly equates to an extra £500–£1,000/ha in additional milk from forage, simply by maintaining sward quality.”

In answer to Prof Newbold’s prompt on growing better quality silage, Volac scientist Dr Mark Leggett said new farm-based Ecosyl research had examined the potential of multi-cut silage – where grass is cut younger and more frequently – to deliver extra milk.

Results confirmed that grass from a five-cut system was indeed more nutritious than from a more traditional three-cut approach – with an average digestibility (D value) of 72.7 versus 69.7, and delivering 0.5MJ/kg more energy. Crude protein content was also almost three per cent higher.

“Based on 5.3MJ being required to produce one litre of milk, this means this particular multi-cut system had the potential to deliver an extra 3,506-litres/ha of milk,” explained Dr Leggett.

“At a milk price of 25p/litre, this is equivalent to an extra £877/ha earned, which would still leave you about £333/ha better off after deducting the extra cutting costs.”

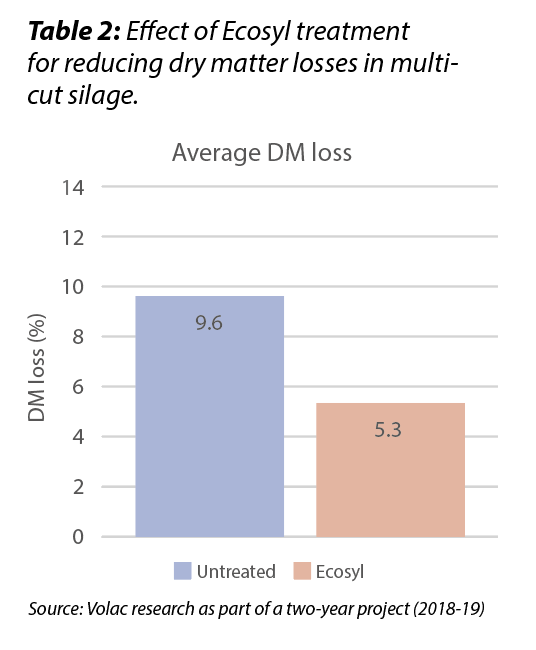

But while multi-cut grass has the potential to unlock more milk from forage, this is only half the picture, Dr Leggett stressed. You also need to conserve these extra nutrients within the silage.

“Although multi-cut offers nutritional benefits, it can be more challenging to ensile,” he explained. “Its higher protein can contribute to buffering of the fermentation, while shorter cutting intervals can mean less time for slurry to dissipate, and so increased risk of slurry bacteria, enterobacteria, being present, which can produce DM losses.

“Indeed, our research found that when multi-cut was allowed to ferment without an additive, not only was the fermentation slow, with enterobacteria continuing to grow, but the average DM loss was nearly 10 per cent. By comparison, average DM loss was virtually halved when treated with Ecosyl additive, and there was clear evidence of better protein preservation.

“It was concluded that multi-cut offers the potential for more milk from forage, but this cannot be realised without careful ensiling, and Ecosyl helped to ‘bank’ its potential,” he added.

Compact TMR feeder attracts interest

The new version of BvL’s V-Mix mixer wagon, designed specifically for use with compact TMR, attracted considerable interest when it launched at Lamma in January, due to its potential milk yield benefits.

Compact TMR involves soaking and pre-mixing the dry components of the ration with water, leaving it to soak overnight before adding the rest of the ration mix. This makes it impossible for the dry components of the forage to be separated out from the rest of the mix, so every cow is fed a far more consistent ration, resulting in a yield improvement of up to 2-litres/cow, in addition to potential improvements in milk quality.

There are now compact TMR versions of all models in the BvL V-Mix range. The company also launched a new app-based weighing and feed management system for use with the Compact TMR V-Mix. The new V-Dairy Feeder TMR system is designed to allow quick and easy access to information on the ration mix, from multiple mobile devices at once if necessary. It allows users to achieve the accuracy and consistency that are key to optimum results from compact TMR. Both android

and Apple iOS versions of the app are available.

Improving your grassland

It’s been a well-known fact for many years that harrowing grassland in the spring not only assists in removing old sward and weeds, but also helps to release nitrogen to the growing grass. Originally this operation was carried out with chain harrows, but today the grass harrow has evolved into a much more versatile piece of machinery with levelling boards, tines that can be angled, and rear packers. The ability to improve grass leys by distributing seed via a mounted airseeder on the harrow has also improved the efficiency of the operation. A full re-seed including ploughing can be an expensive operation, so the ability to stitch seed into an existing ley and extend its life can be beneficial.

The Grass 300 from Bullock Tillage comes complete with a hydraulic front levelling board which can be replaced by individual tines for greater disturbance. Three rows of adjustable tines and a hydraulically controlled prismatic packer which ensures a good level finish and is used for depth control. The addition of the SP200 airseeder, which has either GPS or land wheel drive, means the Grass 300 can handle all operations required for grassland management. James Dixon Agricultural Service, based in Suffolk, is the new distributor for Bullock Tillage equipment in the eastern counties.

Plan liming now for low pH soils

Low pH compromises yield and quality, as acidic soils can cause slow plant growth and reductions in nutrient availability of forage crops and grassland.

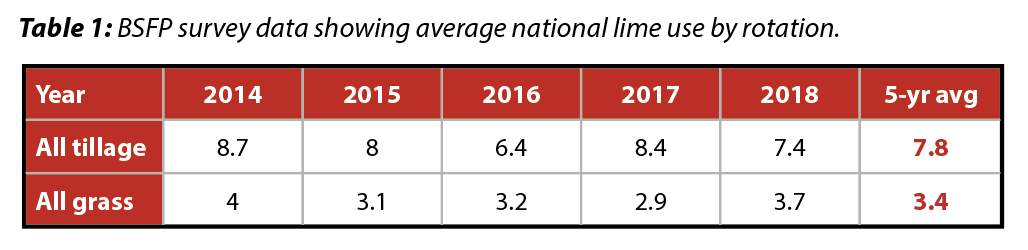

The five-year average data from the British Survey of Fertiliser Practice (BSFP) demonstrates the continuation of low levels of liming in both arable and grassland rotations, as shown in Table 1.

The survey shows that only 3.7 per cent of grassland was limed in the UK in 2018, and the 5-year averages are equivalent to liming grassland on a 31-year cycle. A pH below 6.5 on mineral soils will start to impact the availability of major nutrients – greatly reducing the yield potential, along with herbage quality.

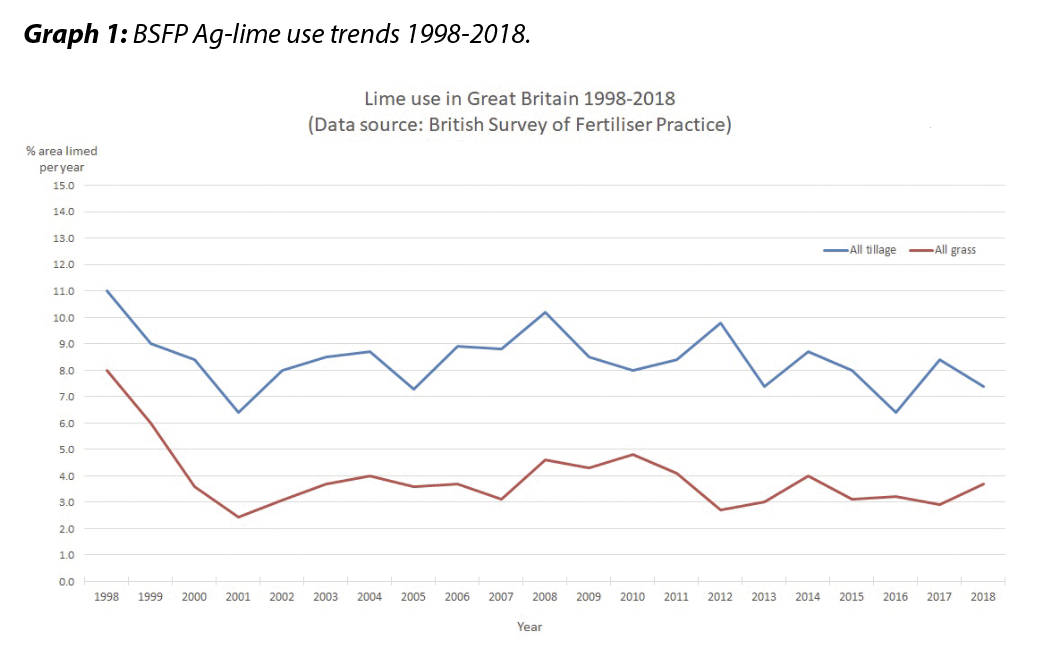

Graph 1 shows the 20-year lime use trend for all BSFP survey fields in tillage or grassland rotations.

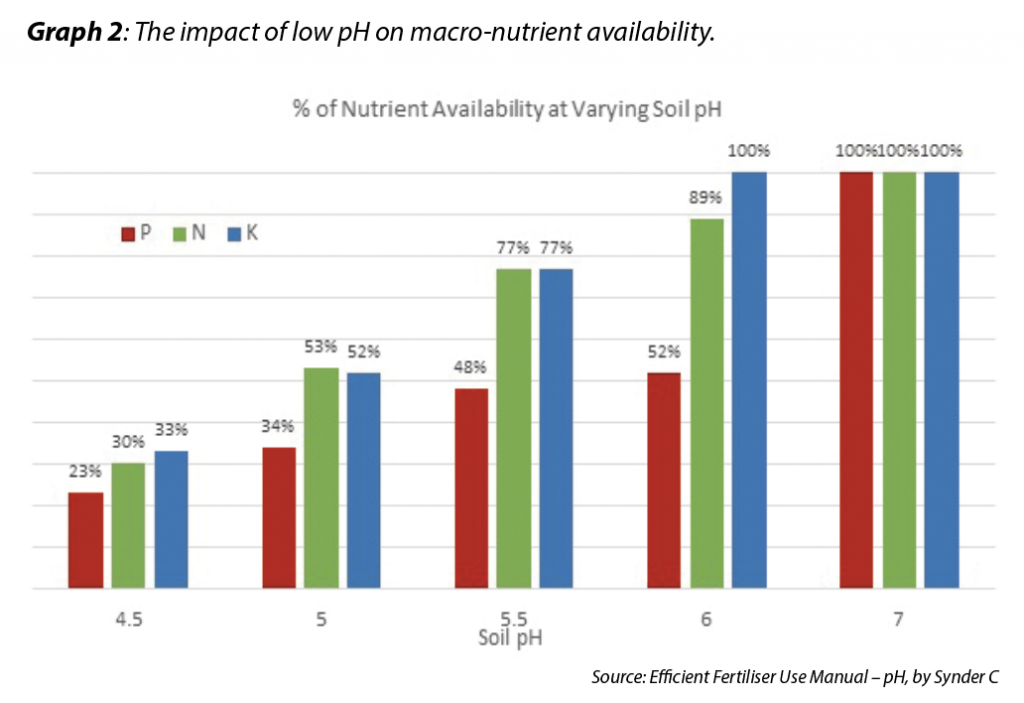

Of the 135,000 grassland soil samples analysed by the 2018/2019 PAAG survey, 57 per cent were below pH 6. Graph 2 shows the impact of soil pH on nutrient availability with significant reductions at or below pH 6 highlighting the importance of getting the pH right before thinking about other inputs.

Get your soils sampled for pH

Ignoring pH can prove costly, so make sure to keep on top of sampling and