Pioneering venting tech offers faster milking and better yields

27th September 2021

ADF Milking’s InVent (Intelligent Venting) system won the new product competition at this year’s Dairy Day (15th September).

The new InVent system, developed by ADF Milking, uses pioneering venting technology that controls the vacuum within its liners, to provide cows with a more comfortable milking – which in turn leads to faster milking and improved milk yields.

Last year, Church Farm invested in the ADF Milking system with InVent included to improve the health of their herd and increase their yield. Two months after installing, they are saving 1.5 hours per milking due to a much faster, simpler milking routine and collecting over 500 litres more milk per week. Herd health has improved dramatically and their cell count rolling average is now 80,000.

Church farm dairy manager Stuart explains: “Before we installed the ADF system we were struggling to get relief milkers because milking was such a lengthy process. Now the venting system has really sped up the flow of the milking parlour and when I hear the last cluster come off, I can let that side go straight away knowing that the cows have been dipped.”

ADF explains how venting can overcome teat damage during milking…

What happens to the teat during milking?

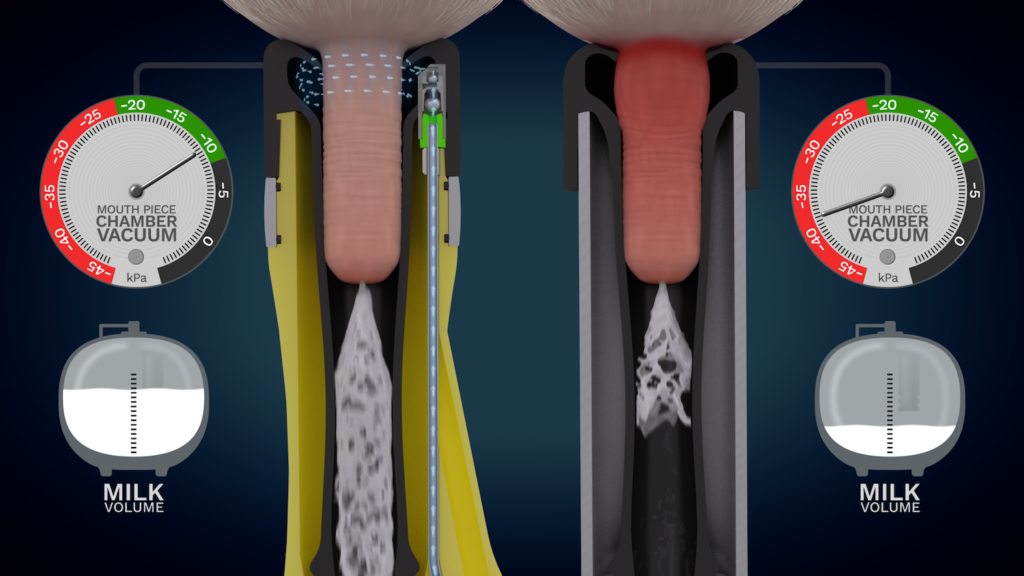

At the beginning of milking, the cow becomes stimulated and the teat becomes plump and engorged. When the teat goes into the liner, the vacuum causes the teat’s dimensions to change dramatically. It immediately doubles in length, becomes narrow and elongated. This creates a passage for excessive vacuum to travel up to the head of the liner.

The teat shape and size will also be affected by how engorged it is. The amount of milk entering the teat at this time is dependent on individual cows and the degree of stimulation before milking.

At the start of milking, prior to full milk let down, it is common for excessive levels of vacuum to build up in the head of the liner. This is undesirable as not only does it cause discomfort for the cow but also the liner to cause oedema and swelling, which is counterproductive to good milk let down.

Once the cow is in full milk flow, the teat plumps up, filling the barrel of the liner. At peak milk flow, vacuum reduces in the short milk tube and we have the ideal milking conditions. Typically, vacuum in the liner is under control.

Towards the end of milking as milk flow decreases, again, there is a passage for vacuum to travel into the head of the liner, which has the effect of reducing the speed of let down and delaying cluster take off. This results in unnecessary trauma to the teat end. Vacuum is now high in the short milk tube, delaying take off and exposing the teat to ‘close to system’ vacuum, which is highly undesirable. This is when teat damage occurs.

When a cow is suffering discomfort or pain, she produces adrenaline. Adrenaline cancels out the effects of oxytocin, the result of which is low milk yield and extended milking times.

The benefits of venting

Venting prevents excessive vacuum that causes swelling. With InVent the teat is subject to less trauma and therefore reduced risk of oedema, ADF says. Therefore, InVent improves the teat condition, improves flow rateand provides more comfortable milking.

It is desirable to have a vacuum in the liner hood/head of between 10 and 15 kPa to prevent liner slip. Vacuum above 20 kPa is considered detrimental to the teat.

A big benefit of venting is you open up the range of teats for which a liner is suitable. It’s impossible to milk every teat with the exact size of liner needed because there are differences between cows and differences between teats in the same udder. Venting enables effective milking on a wider range of teat sizes and shapes.

Results of InVent are calmer milking, less stress for cows and cow comfort. The benefits of that are increased milk flow, improved teat condition, improved udder health and cow longevity.