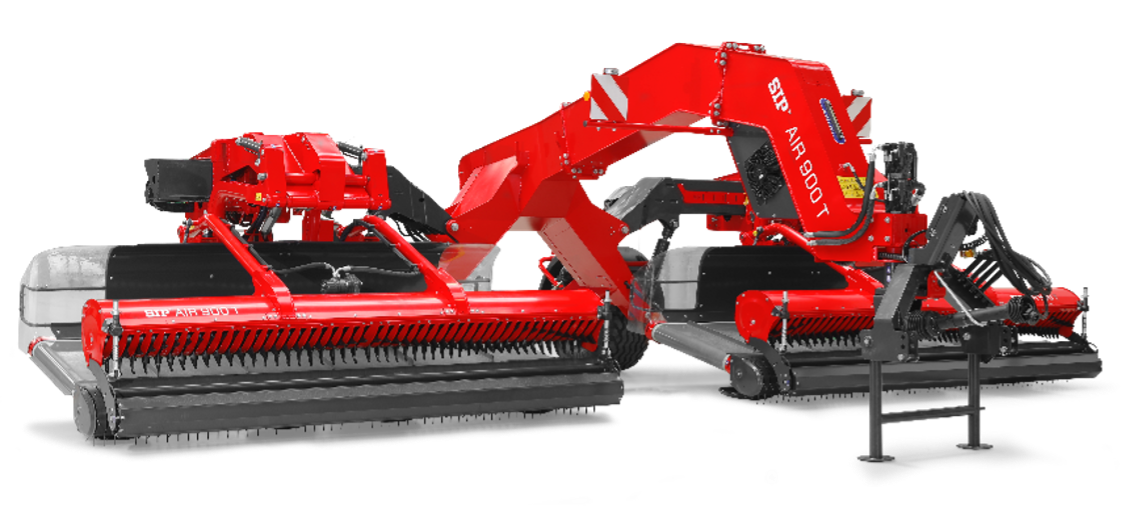

AIR 900 T – A step forward in raking

30th January 2023

SIP presents a step forward in raking technology, the innovative trailed pick-up rake AIR 900 T. The combination of a patented flexible pick-up unit, rotor accelerator, and conveyor belt enables the formation of

SIP presents a step forward in raking technology, the innovative trailed pick-up rake AIR 900 T. The combination of a patented flexible pick-up unit, rotor accelerator, and conveyor belt enables the formation of airy and evenly distributed swaths. The rake is designed to prevent the loss of sensitive leaves and the introduction of soil and sand into the swaths, thus ensuring the harvesting of high-quality forage.

The design of the telescopic arm and two trailed pick-up units give the versatility of raking – working width of 9 m for central and 7 m for side swath delivery. High clearance between the frame and the ground and the consistency of the sections result in evenly shaped swaths. When pick-up units are distant the belts transport the forage into the central swath. The distance between the units is telescopically adjustable and the width of the central swath can be optimally adapted for collecting the forage with balers, loading wagons, or harvesters. When pick-up units are placed next to each other, the rake forms a left- or right-side swath. If forage is wet and heavy the units can divide the amount of forage by transporting it into a single left and right swath. Already formed swaths can be also moved and turned around or merged into one swath.

A dual variable hydraulic pump on a 2-point flexible hitch is driven via the PTO shaft enabling even oil flow to the hydraulic motors of the pick-up system. This ensures even operation of the pick-up system also on more demanding terrains, where it is necessary to increase the tractor engine speed and the output shaft. A belt drive with a hydraulic motor allows for speed and rotation direction to be set using the control unit.

The segmented central axis allows the flexibility of the pick-up unit and enables excellent adaptation as it follows the ground along a curved line. This allows harvesting without damaging the turf and no forage residues in the field. Since all forage is picked up from the ground, the yield of DM per hectare of arable land is higher and at the same time, the turf stays undamaged and overgrown faster. A pick-up unit without a cam curve is built from fewer components for quick and easy maintenance.

A well-thought combination of a small diameter pick-up rotor, finger rotor, and front roller on the pick-up unit ensures a smooth flow without turbulence and accumulation of forage in front of the rake and prevents leaf losses, especially in legume forages. Since most of the plant’s crude proteins are in the leaves, using pic-up AIR technology preserves the protein value of the forage and increases the yield of crude proteins per hectare of arable land.

The spring tines on the pick-up unit are curved in the opposite direction of travel and thus produce a trailed effect, which ensures a gentle and fast lifting of forage from the ground and prevents the introduction of soil and sand into the swath. Reduced ash content contributes to higher forage energy, better consumption, improved animal health and welfare, and better milk and meat production. The lower ash content is also favorable for the optimal fermentation of silage and better forage stability. The combination of a flexible small-diameter pick-up device and trailed tines thus reduces the contamination of the swath, prevents leaf loss, and preserves the nutrients in the forage also when working downhill.

The spring tines are protected with a system against loss. This system consists of a split plastic element and a metal clamp. Each segment attaches six spring tines at a time, ensuring quick and easy maintenance. In case of tine breakage, it remains in position and does not enter the forage.

Trailed pivoting with hydro-pneumatic suspension enables excellent adaptation of the system and lowers pressure to the ground on all types of terrain. Additionally, freely rotated skids are installed very close to the pick-up unit ensuring high responsiveness and adaptation of the unit to the terrain. This prevents damage to the turf and ensures less wear on the pick-up unit and because skids rotate freely, no dirt remains on them. A large clearance from the ground during partial lift enables easy driving over the swaths or turning at the headlands. With the capacity of the AIR 900 T of up to 15 ha/h the machine is designed for professional agricultural producers and contractors. The compact transport position with a short frame and hydraulic or air brakes allows for comfortable machine handling and stability during transport.

With the unique pick-up system, the investment in the AIR 900 T rake results in clean forage of higher nutritional value. In alfalfa production, leaf losses are prevented, and the capacity of the rake is higher thus increasing the protein and yield per hectare of arable land.

Advantages of using a pick-up rake AIR 900 T:

- Reduced ASH contentin the forage, higher quality of silage and hay.

- Higher energy valueof forage and better consumption.

- Improved animal healthand welfare and better production.

- Higher DRY MATTER yield per habecause forage residues are reduced.

- Higher CRUDE PROTEINS’ yield per habecause leaf loss is prevented.

- Protection of the turfbecause the forage is gently lifted from the ground.

- Airy and evenly shaped swathsfor easier forage collecting.

- The adjustable swath width according to the pick-up device.

- Higher capacity, reduced harvesting time, and costs of harvesting per ha.

- Easy operationand maintenance of the machine.