Remember field checks and best practice when applying granular nematicides

21st March 2022

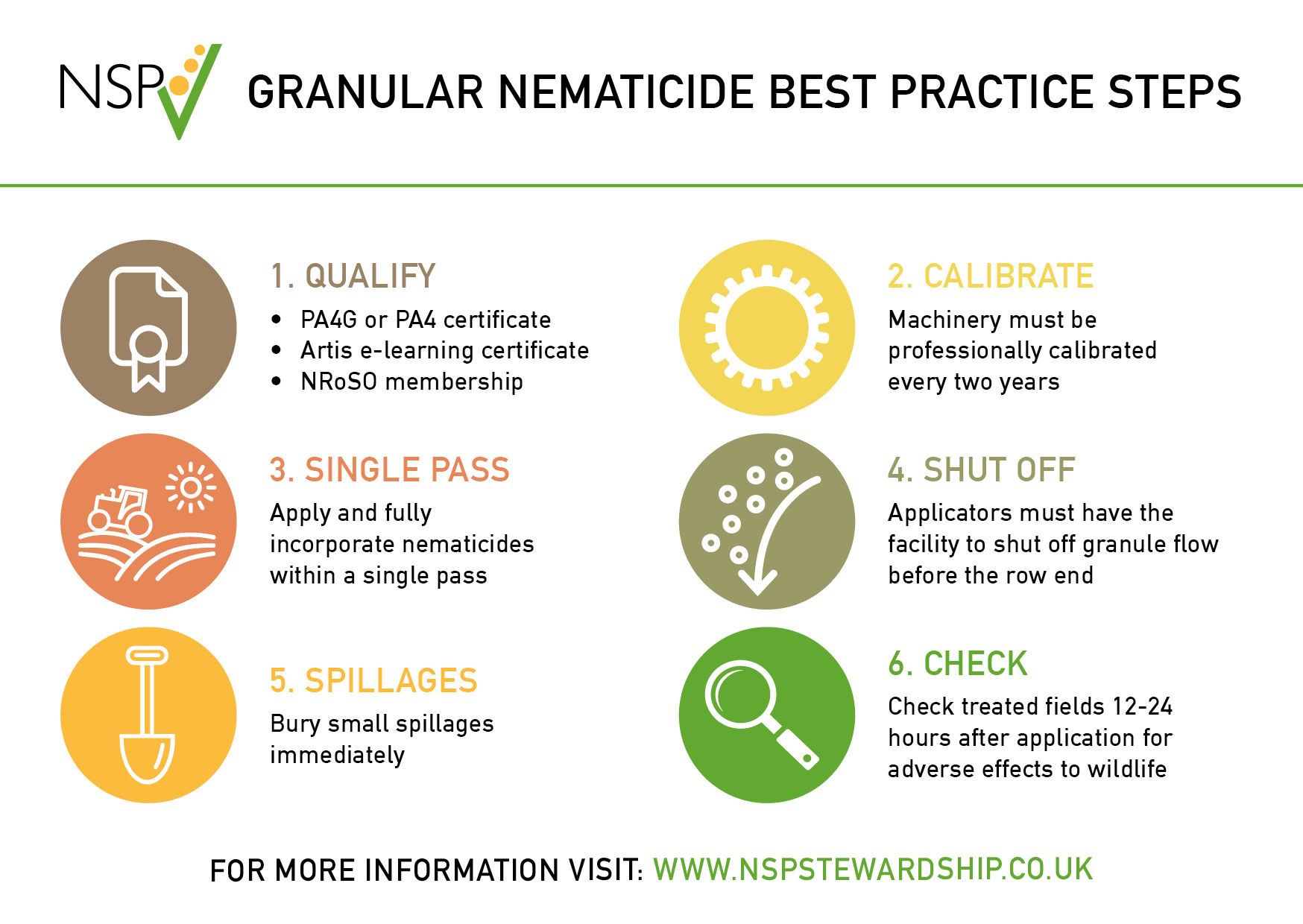

The Nematicide Stewardship Programme (NSP) reminds potato growers and operators to adhere to best practice when applying granular nematicides this spring.

NSP working group member and agronomist, Simon Alexander, highlights that, following amendments to the Red Tractor Assurance fresh produce standard in November 2021, this is the first application season when certified growers will be required to provide evidence of a post-application field check for fields treated with granular nematicides.

“Growers must walk fields between 12 and 24 hours after the application of granular nematicides. This involves checking headlands or other areas where equipment is turned on and off, and also the field edge, for signs of wildlife that may have ingested the product and suffered adverse effects,” explains Mr Alexander.

A field monitoring form is available to download from the Red Tractor website. “The form allows farmers to record their field check process, so Red Tractor can provide assurance that growers are taking every precaution necessary when applying granular nematicides,” he adds.

Operators are also reminded that if they are applying nematicides for Red Tractor certified growers, they must have completed an e-learning module on nematicide stewardship.

“The online training, provided via ARTIS, will ensure operators are familiar with the stewardship principles set out by the NSP, to enable the safe and responsible use of granular nematicides,” says Mr Alexander.

He reminds that the wider best practice steps also need to be considered when applying granular nematicides. These include applying and incorporating nematicides within a single machinery pass, ensuring granule flow is shut off before the row end and burying small spillages immediately.

“To achieve an even application, it’s important to apply granular nematicides in a single pass, with a properly calibrated applicator,” he says.

“The machine should shut off the flow with enough room for all granules to have passed through the system before the row end. This will ensure all granules are incorporated into the soil before reaching the headland.”

Small spillages should be buried immediately, while larger spillages should be gathered into the original container and the manufacturer contacted for guidance on safe disposal.

“Regardless of the quantity spilled, PPE should be worn to protect the operator handling it,” Mr Alexander adds.

He explains that on each day the applicator is used, it should be checked to ensure all pipework is correctly fitted, the hopper bungs are in place and hopper lids are secure.

“Machinery must also have been inspected and certified by NSTS in the last two years,” he adds.

For more information on the NSP’s granular nematicide best practice steps visit their website.

For more arable news, visit our website.