Sprout control in potato stores: Practical solutions for getting the best out of ethylene and mint oil

14th April 2021

AHDB Potatoes recently hosted a free webinar on best practice for the current available sprout suppressants. Rachel Hicks reports.

We’re well into the potato storage season, and in the absence of CIPC many growers will already have applied mint oil and/or ethylene. While some are very familiar with these, others are completely new to them, and as Laura Bouvet of AHDB Potatoes stated upon opening the webinar, as an industry, we are all on

a learning curve.

Controlling sprouting with ethylene and mint oil requires a more careful approach to store management than previously experienced. With these two sprout suppressants, there are some key factors to consider, including how to optimise application rates and timings, store closure periods and the impact on CO2 levels, improving air flow and other store environment measures – all of which will have an impact on how these suppressants will work for long-term storage.

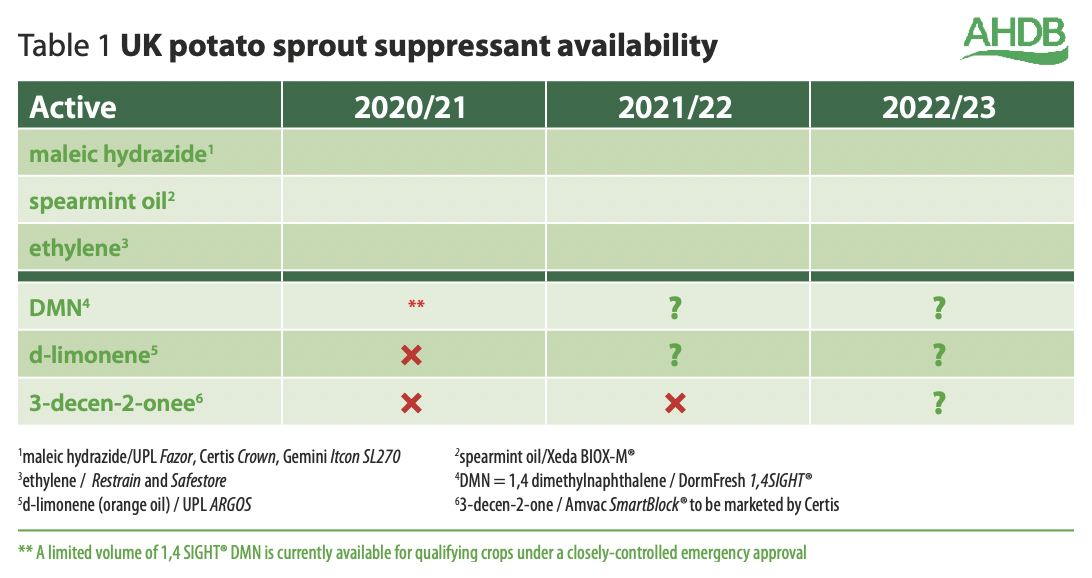

Head of Sutton Bridge Crop Storage Research Adrian Cunnington stated: “As a summary of sprout suppressant availability, at the moment there’s no certainty beyond the current choices. We obviously have an emergency authorisation under very tight control on DMN, but it’s not clear if this will continue to the next season or whether full approval will be forthcoming either.

“There’s a lot of work going on in the background to bring on these new actives, and reports on progress will be made as soon as AHDB can.” See Table 1 for a list of current and future options and their status.

Fresh market options

Discussing the options for the fresh market, Mr Cunnington said that, while it ought to be possible to use little or no chemical in cold storage, it depends on the dormancy of the variety, whether there are extended loading periods, the impact of storage temperature on acrylamide mitigation, or whether the temperature of storage varies across the store due to airflow, insulation etc.

For longer term storage, growers may need to accept that an in-store treatment has to be used, with the two primary options being spearmint oil and ethylene.

According to Mr Cunnington, there has been some evolution of the label for spearmint oil, so he recommends that growers speak to their contractor before using this chemical in order to ensure proper use. In the UK, the distributor for spearmint oil is Juno Plant Protection LLP, sold under the name Biox-M.

It’s a crucial requirement before applying mint oil to ensure the crop is completely dry before application. In order to do this, AHDB’s advice is to:

Run fans without cooling for at least 24 hours prior to application

Work with your contractor to ensure the store is set up correctly

Use reduced speed fans to recirculate mint oil – need to strike a balance between moving enough air/fog and risking localised concentrated deposits of chemical on the crop which could lead to oil ‘burn’.

The other treatment option for stores is ethylene, which is applied through Restrain generators or via Safestore cylinders. It doesn’t have a great deal of residual action, so is widely used in fresh markets but not so suitable when it comes to shelf-life markets.

There is a caution on using ethylene in chip shop varieties, said Mr Cunnington, as there are concerns around the lack of research into ethylene sensitivity for a number of chipping varieties.

“We are definitely not using ethylene or mint oil as a ‘plug and play’ option as a direct replacement for CIPC,” explained Mr Cunnington. “In order to work with the chemistry, we need to look at combinations of sprout suppression products, management of closure periods and consequences, and choice of temperature and variety.”

Changing practices for potato storage

Mr Cunnington iterated that attention to detail is incredibly important, with store sealing, flushing methodology and temperature all playing a key part. “We don’t want products like ethylene leaking out into other stores where it is less suitable. It’s expected that we will see an increased use of refrigerated storage compared with ambient, when it comes to storage using these chemicals.”

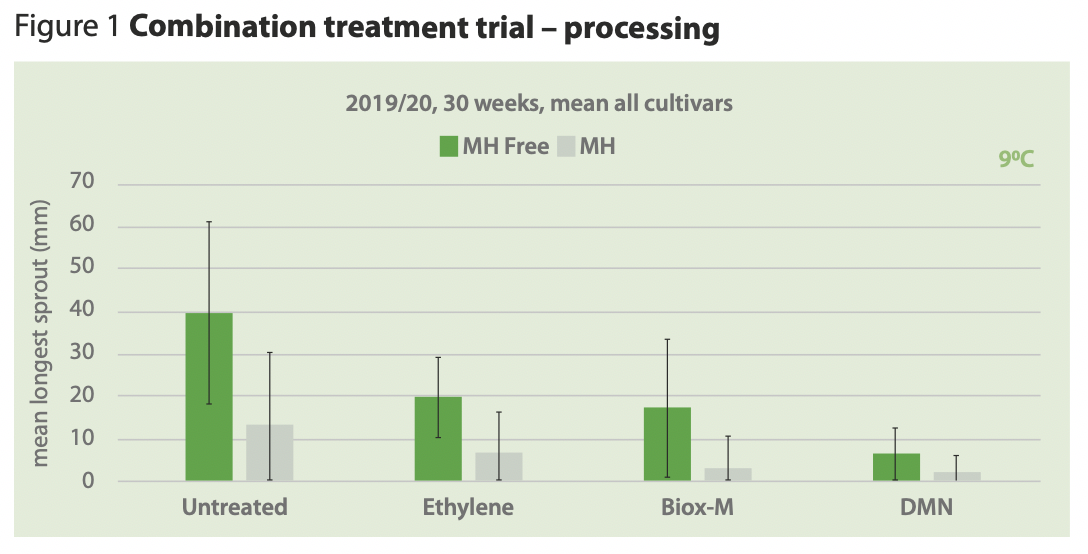

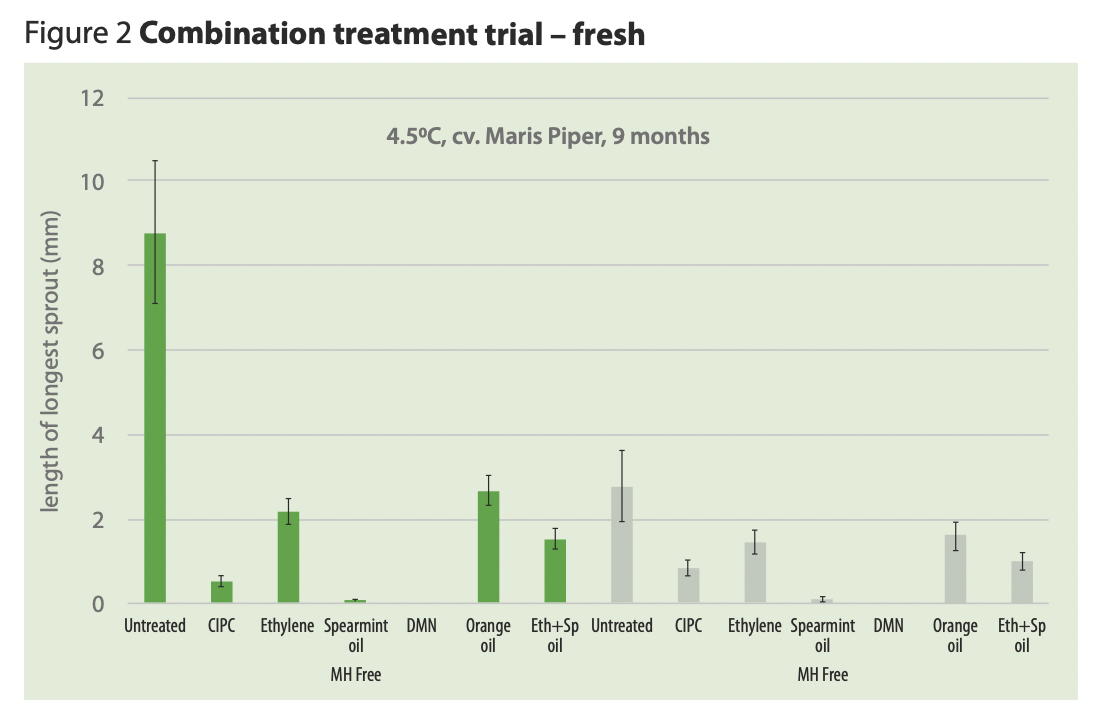

In combination treatment trials for both the fresh and processing markets, AHDB Potatoes found that the use of maleic hydrozide (MH) in addition to the other chemical options gives a significant improvement of sprout control over MH-free and this residual control is something that needs to be understood better (see Figures 1 and 2).

When considered at 30 weeks, the research shows that the residual component of MH provides a level of control across shelf-life which isn’t being afforded by the MH free treatments, so it’s important to consider the impact and value of MH – the likes of which hasn’t been seen otherwise since the loss of CIPC.

AHDB is also running a significant amount of testing on chipping and crisping varieties in terms of their reaction to ethylene. The data it has gathered is based on one year’s work from a single trial with around 50 varieties tested, but AHDB is quick to point out that there are some anomalies and variations within the data, so at this stage it is treating it with caution. At least another year’s data needs to be under the belt before making recommendations.

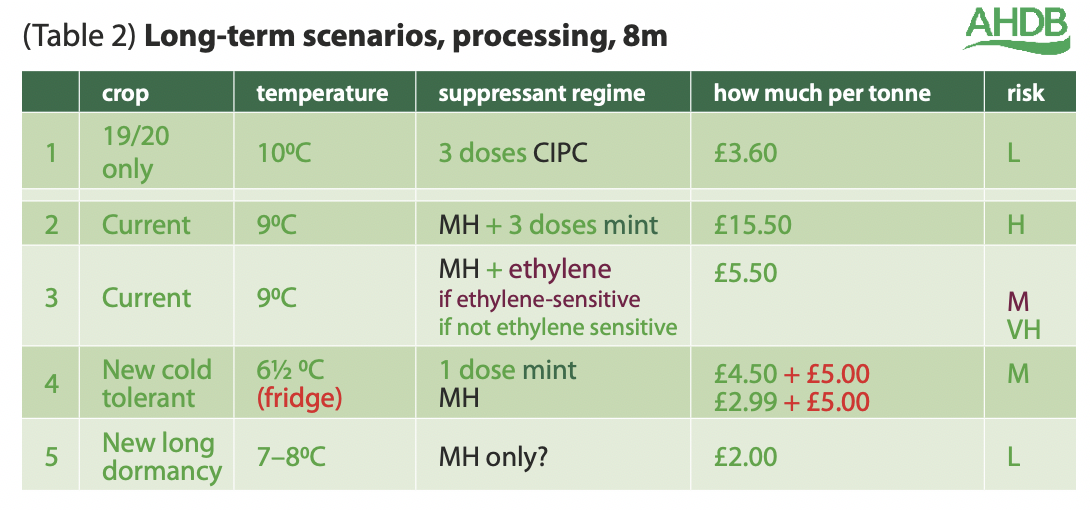

Of course, cost is always going to be a driving factor when deciding on treatment options. Table 2 suggests some long-term storage scenarios for the processing market, comparing price for each suppressant regime and comparing the level of risk. One thing is clear from the data – particularly for long-term storage, the main consideration is that we need newer longer-term dormant varieties which don’t require such reliance on chemicals.

Integrated potato store management:

Mr Cunnington summarised by saying IPM is the key for the future of potato storage. While chemical treatments are the final piece of the puzzle, growers need to ensure good management and intervention, by ensuring a good level of physical and biological cultural controls (e.g. temperature, drying, atmospheric composition), managing risk using monitoring and assessment, decision support, and disease and quality forecasting, being cleverer in the way we predict our store qualities so we only store the varieties that give the best returns, and that looking at the bottom of the production triangle, we need a strong base in terms of genetic traits – offering low temperature tolerance, reduced acrylamide formation, and longer natural dormancy.

Effect of store closure on CO2 levels

SBCSR crop storage scientist Adrian Briddon also spoke at the webinar. He added that, while both ethylene and mint oil have previously been used in the packing sector, their use in the processing market has given rise to some significant changes in practice (alluded to earlier by Mr Cunnington, when he mentioned the label changes for Biox-M). One key difference is the greater frequency of applications and reapplications, not to mention the store closure period.

At this stage, the idea is to prevent active ambient air exchange. With CIPC this was straightforward – 6–8 hours after application was complete, the fog was settled and growers could flush the store without losing treatment products.

With Biox-M however, the store must be kept sealed for 48 hours minimum – although if the store is part-filled, it should be left for even longer. This gives rise to the issue of CO2, which is created by the potatoes and which cannot be expelled when the store is sealed for such a long period without active ventilation.

This means CO2 could accumulate in the store.

Following trials with Biox-M, with a store closure of three days rather than two, there was a dramatic effect on the CO2 levels.

While there is a human health implication here, the potatoes seem unaffected with no change to fry colour as long as ethylene is absent. Mr Briddon then stated, however, that “exposing crops to CO2, if they then have a sniff of ethylene, is damaging. We therefore must not use conventional foggers – we must use electric or heat exchange foggers only for extended closure periods, if using Biox-M for sprout control.”

Impact of ethylene on fry colour

When it comes to ethylene, all the work at Sutton Bridge in recent years has used the 10ppm rate initially introduced by Restrain. That said, Mr Briddon did point out that external literature suggests the rate can go down to 4ppm without affecting efficacy, although this has not been confirmed in AHDB trials to date.

What is clear is that ethylene influences fry colour, and this effect can be slight or severe.

Mr Briddon pointed out that, with careful management, there can be a negligible effect on fry colour however. Using Biox-M as the industry standard, as long as there is careful management with the initial start-up, fry colour issues are more about risk than actual issues. Wider use for chips seems appropriate, but there is a level of nervousness on the crisping aspect.

Mr Cunningham concluded the webinar by saying: “At the end of the day, we need to get all the best tools into the toolbox and this might take a bit of time.”

Real results

Colin Davey is stores manager for Spearhead Potatoes and has been using Biox-M treatments throughout his stores, with no ethylene. He said he has seen acceptable levels of control in bulk stores, but that results haven’t been as good in boxed stores. In order to increase levels of control in the boxed stores, he has had to increase air flow in order to move the chemical around the space, as he was finding there were pockets which weren’t being touched by it.

As far as the application regime is concerned, this is being carried out by a respected contractor, using one of the new heat exchange fogging systems which, Mr Davey says, seems to have reduced the risk of CO2 build-up.

On top of that, he is also not seeing deterioration of sugars or fry quality, allowing them to keep the stores closed a little longer to improve the efficacy of the control. Typically, he is leaving stores closed for 72 hours as a rule, as he is finding that gives better control rather than early applications at 48 hours.

A couple of stores have been closed for slightly longer, with better scorching back of the sprouts and no issues with fry colour. Mostly he is using a 60ml/t dosage, occasionally 90ml where it’s been needed but that’s not manageable in the long term as the regular dose for the bulk stores.

Mr Davey reckons MH has definitely been giving an advantage this season, showing the benefits of good MH uptake. He has concerns they may struggle in seasons where there is less good MH uptake and considers DMN an interesting potential option for the future.

To watch the full webinar visit https://ahdb.org.uk/webinars