Partnership means high-spec cost-effective solutions

12th February 2021

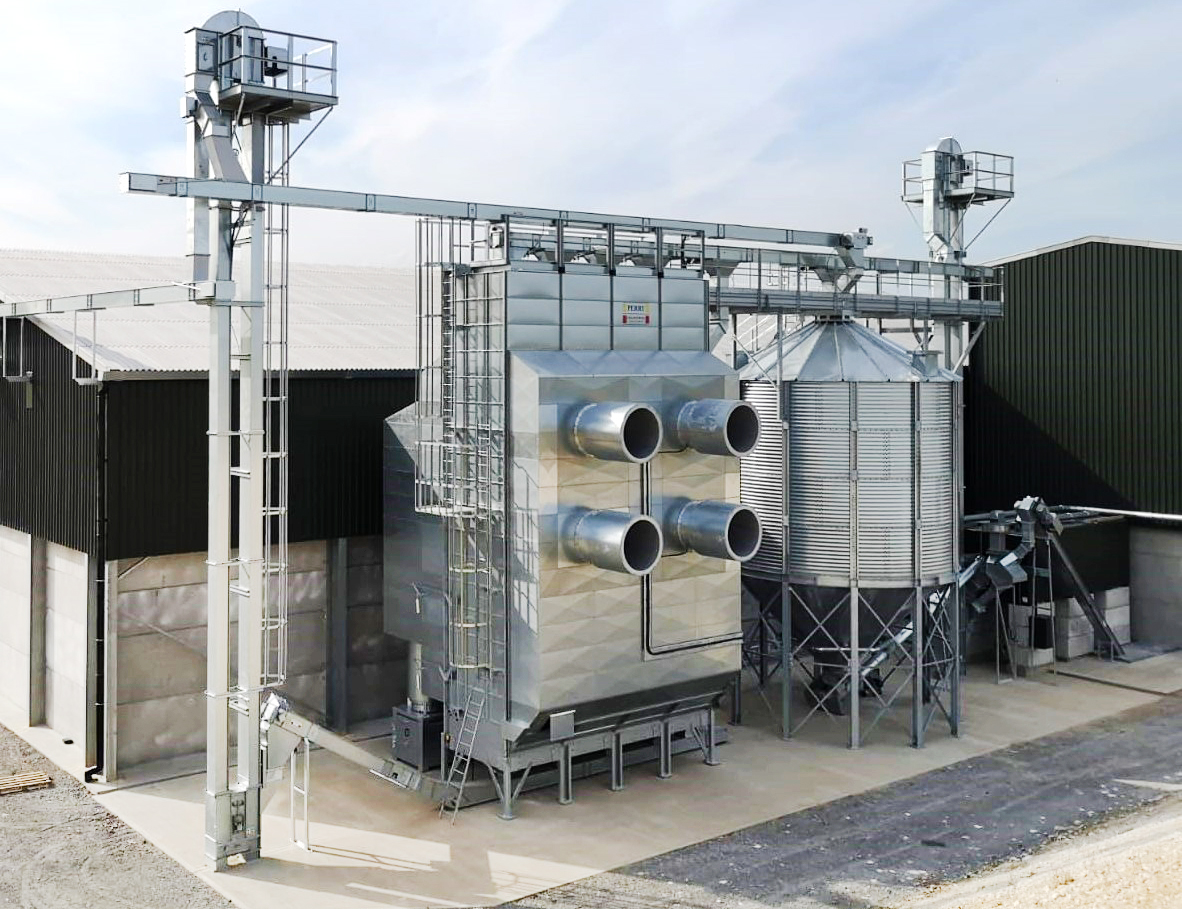

With over 70 years’ experience in manufacturing bulk materials handling, drying and storage equipment, Perry of Oakley Ltd provides high quality machinery to a wide variety of industries, including farms, commercial grain stores, waste and aggregate industries, feed and pet food, pharmaceutical and biomass industries, and many others.

The company has supplied machines to over 25 different countries across four continents. In 2019, Perry announced a new partnership with SiloMasters.

Together, the two companies provide an extensive range of at-bottom and hopper-bottom silos. The silos are designed and manufactured to the highest specification while remaining a cost-effective option.

Each silo is dual-branded with both company logos, as a symbol of their cooperation in providing customers with a full tailored package.

Flat-bottom silos range from 3–32m giving storage capacities from 27–26,000m. Hopper-bottom silos range from 3–13m diameter with either 45 or 60 degree cones.

The hopper silo ranges can be manufactured with either a heavy-duty hip ring or with an internal light weight hip, ensuring the most cost-effective solution can be supplied for specific requirements.

In addition, within the scope of supply will be:

• Complete aeration systems

• Temperature control systems

• Unloading equipment

• Walkways and catwalks

• Towers and structures

Perry’s also supplies a full range of handling and drying equipment. To find out how Perry’s can help with your handling, drying and storage requirements, contact the team.