Latest updates to Vogelsang’s Blackbird range unveiled

21st November 2024

Vogelsang presented the extended Blackbird family of trailing shoes in Essen, Germany recently. Neale Byart was there.

Offering maximum variety in a single series, the Blackbird range of trailing shoes come in four distinct model ranges, that are available in a variety of working widths from 7.5–30m, and Farmers Guide experienced several of the range in the field, with Vogelsang export manager agriculture, Hubert Schmidt talking through the details.

Vogelsang has also launched the X-Split slurry separator and a new macerator pump, both of which we were given demos of during a brief factory tour.

Founded in 1929, it was not until 1970 that Vogelsang ventured into the market they are known for today with the second generation of Vogelsangs inventing a rotary lobe pump.

By 1980 they were producing dribble bars and today the company is run by the third generation and is known almost exclusively for pumping, shredding, mixing and separating difficult substances. While agriculture does amount to around 30% of its business, Vogelsang is also prominent in biogas, wastewater, transportation and industrial industries.

X-Split

The new X-Split separator is said to be low-maintenance and easy to service. It combines a flexible stainless-steel screen with options for 0.5mm, 1.0mm and 2.0mm sieve screens with a robust stainless-steel auger. Sieve elements can be replaced individually and easily, and it can deliver flow rates of up to 45m3 per hour, with a dry matter content of up to 40% of the digestate or slurry.

The X-Split uses an elastomer sealing disc at the solids outlet and this is where the drive motor is also mounted to keep it safely away from any liquid. The pressing area can be quickly adjusted using a threaded spindle for a higher dry matter content. The separator can be supplied on a fixed or lifting frame with a variety of control options depending on the end user’s needs.

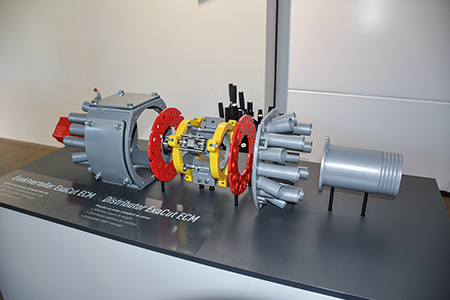

ExaCut ECM

The macerator, or distribution head, is the heart of every trailing shoe or dribble bar and Vogelsang says it is dedicated to making them the best they can be.

The ExaCut ECQ macerator, with its innovative eccentric adjuster, is the top-of-the-range model and available on all Blackbird models, but there is a new option, which comes with some unique benefits.

The latest ExaCut ECM eliminates the stop/start delivery that you often get with macerators due to the breather sucking in air, which can result in uneven slurry distribution.

There are no breathers on the ECM, so the delivery is not disturbed by air and the pressure in the chamber is constant, meaning the feed to the shoes is uninterrupted. This has been achieved with a completely redesigned cutter plate, and the whole unit is more compact and lightweight than the ECQ and comes with low wear and a long service life. Cutting knife life on the new ECM is expected to be around 60,000m3+.

When maintenance is required, the ExaCut ECQ is simpler, as the whole inner assembly slides out through a side opening in the case. It is said that it can be dismantled, serviced and put back together within an hour.

The ECM, on the other hand, is a little more involved as the compact body means that dismantling will need to be undertaken from the end plate with its numerous hose connections. The ECM also requires a slightly higher operating pressure at 0.3bar, compared to 0.2bar for the ECQ.

A single ECM or ECQ is good for injectors up to around 12m working width, with duel, triple or quadruple distribution heads used on larger bars. In the test area we were given a demonstration of the ECM’s ability to deal with solids during which we were invited to feed metal wire and rope into the macerator, which it dealt with effortlessly.

The Blackbird family

Originally launched in 2019/20 with 15 and 18m models, the Blackbird series has been revamped and relaunched under four new ranges, with a brief to make them lighter and stronger. The principles are similar to other injector bars, with a centrally mounted distributer head/macerator on the smaller models and two, three or four on the larger bars.

On every Blackbird the hose routing is optimised to ensure an even and consistent distribution to all outlets, with Vogelsang’s own tests indicating a maximum time of two seconds for liquid to reach all outlets at the start of spreading, with some smaller models taking less than one second, and a variable coefficient between outlets of no more than 1.4%.

They also come with a unique design of trailing shoe to deliver an even, narrow and vertical flow of slurry over the entire outlet length and have 12kg active pressure on the skids. The plastic, or cast iron and rubber, shoes are mounted on leaf springs and use minimal components for a simple assembly and reliable service. The shoes are also available in a double spout option for 12.5cm row spacings.

They come with four-point mounting or direct attachment, 3D collision protection on each side, mechanical or hydraulic section control, LED boom lighting, and DropStop spill prevention by swivelling the boom upwards when work is finished.

Blackbird Single

Named due to its one, centrally-mounted, ECL or ECQ distribution head, the single is available in 7.5, 9.0, 10.5 and 12m working widths and is ideally suited to small farms. When combined with a 2.0m tank width, the single folds up to deliver a 2.55m transport width.

It comes with a slimmed down and optimised rear frame for ease of installation and a low overall weight, with the range starting at just 870kg for the 7.5m version, increasing to 1,050kg for the 12m model.

The single range does not come with support wheels but does include Vogelsang’s 3D collision protection on all but the smallest model. The single is available with limited options to deliver an affordable trailing shoe.

Blackbird Pro

Currently available in two models – a 12m and 15m – the range is due to be extended to include an 18m version in the future. Both models offer weight savings over the outgoing versions, with the 12m coming in at 1,475kg – a saving of 175kg – and the 15m model shaving 200kg off the weight of the previous model at 1,550kg.

The Pro comes with two of the new ECM distribution heads, or ECQ if the customer prefers, and a transport width when folded of 2.99m. As the name suggests, it is offered as a ‘professional’ solution and as such comes with a wide range of options making it very individually configurable. The Pro is available with full headland management, which gives one button flow stop and fold, and one button unfold and flow start when lined up and ready to go again.

Blackbird Light

The Light range is, in effect, a lightweight version of the Pro and comes with fewer options. Like the Pro it is available in 12.0m and 15.0m versions with a transport width of 2.99m and comes with 3D collision protection, and uses two ECM macerators. However, the Light range uses plastic skids, as opposed to cast iron ones on the Pro.

Wear differences between the plastic and cast-iron skids are said to be negligible, with Vogelsang reporting no noticeable difference.

It has support wheels, and the same arms as the Pro, but comes with a more simplified mounting frame that continues to offer durability, but aids in keeping the weight down to 1,325kg and 1,400kg respectively.

Blackbird Max

The Max trailing shoe is still at the prototype stage and not yet commercially available, but we were still able to see the test model in the field during our visit. Available as a single model, the Max comes with four-stage folding that delivers three different working widths from one machine, with options to set it up at 21m, 24m and 30m working widths.

It comes with four distribution heads and the cab operated automatic section control will individually close off outlets that are folded and not being used when operating the Max at anything other than its full size. It does this via individual ‘balloons’ in each of the outlets that are inflated to close off the non-used hoses.

It can also have manual section control whereby hoses are closed off with valves at the distribution head when not needed. The Max can deliver a flow rate of up to 14,000 litres per minute and weighs in at 5,800kg.

Read more machinery news