Agricultural automation offers reliable solutions to today’s volatile world

5th May 2022

With Brexit, Covid-19 and, more recently, the Russia/Ukraine conflict, British agriculture is being strained more than it has been since the outbreak of World War 2. With volatile input markets and labour shortages causing farmers to question whether high input crops such as potatoes are a viable long-term option, efficiency and adding value to produce will be key to survival; but what can automation and robotics do for you?

Bradley Engineering Ltd offers a range of automation equipment designed to keep costs to a minimum and give fast return on investment. Farmers Guide spoke to Richard Bradley, owner of the company, to find out more:

Q: How can automation combat labour shortages?

A: “With good quality labour being in high demand and low supply, the cost is sky-rocketing. Couple this with strenuous, menial tasks such as palletisation, and it can be difficult to find people willing to stack potatoes. There have been automated palletisers on the market for a few years; however, they had their limitations, either being too costly to warrant for the smaller grower or by being too slow to keep up with a packing line producing more than 8–9t/hour. The Agristack range of palletisers from Bradley Engineering solves both these problems, with machine capacities up to 20t/hour and price points to suit every budget. Fully refurbished robots integrated into a new palletising cell can save up to 50% versus an all-new installation.”

Q: Don’t robotic palletisers stack poorly compared to other types of palletiser?

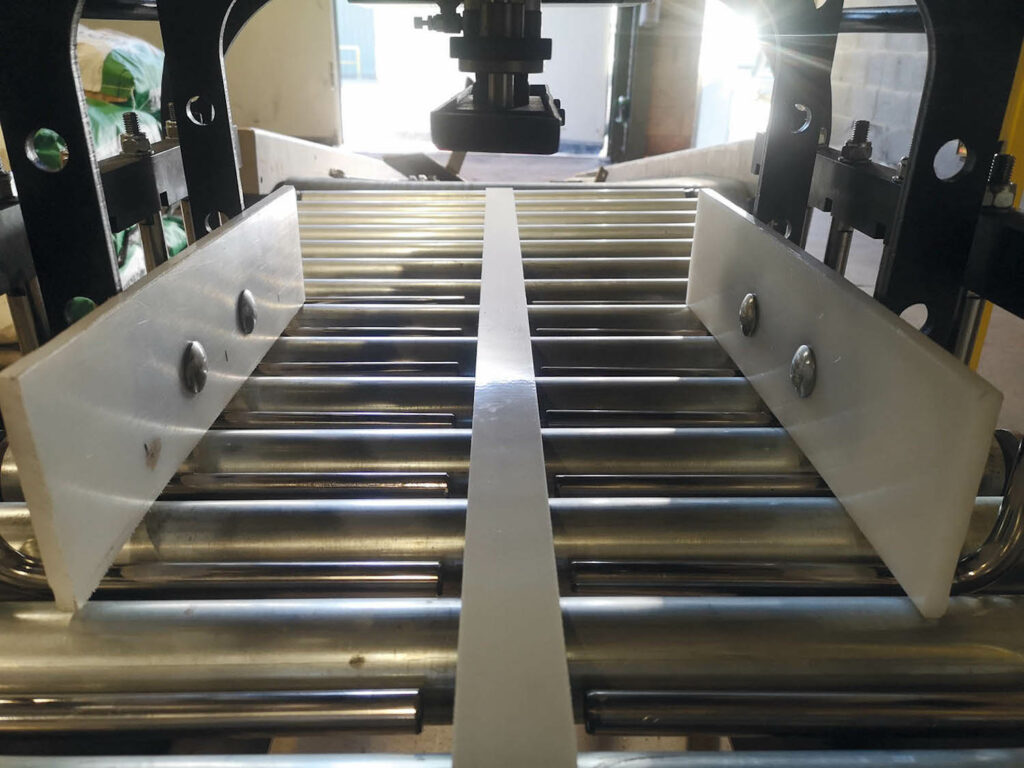

A: “In the past, robotics have gained something of a reputation for producing an unreliable stack pattern. In short, technological advances in hardware and software make modern day robotics accurate to fractions of a millimetre. Couple this with Bradley Engineering’s gripper design with its bag handling and presentation equipment, and robotic palletisers now give a consistent, high-speed output which puts to rest the problems of the past. Robotics also have a unique ability to be adjusted for the type of product they are stacking on the go – meaning when samples are bolder or bags are a different specification, you can easily tweak them and soon be back in full production.”

Q: What type of products can I palletise?

A: “Bradley Engineering offers a full range of robotic end effectors and material handling solutions to give one of the most versatile machines on the market. The standard bag gripper is adjustable from 5–25kg bags, able to switch between products at the flick of a switch. Other items which can be stacked as standard include cardboard boxes, maxi-nest trays, hessian bags and bales. If there is a unique solution required, Bradley Engineering designs, tests and builds custom robotic end effectors such as a special three bale vacuum head, developed recently alongside a customer to palletise haylage.

“The versatility of an industrial robot is such that it can be quickly redeployed to other tasks such as material handling and palletising different products. This means that as your business evolves, the machine can evolve with you. Palletising different products with minimal setup to give you opportunity-based value that may previously have been missed, or too much work to justify.

“Bradley Engineering can also offer a range of pick and place robots, designed to be used to fill cartons, boxes and trays with product ready for palletisation further down the line. These can be complete food grade specification and washable.”

Q: Is it true that robots are expensive and take up a lot of space?

A: “The range of palletisers from Agristack are compact and affordable. With advances in safety technology and position monitoring software, robotic cells are becoming smaller and smaller. A typical single bay palletiser is now no larger than 4x4m and if placed into a corner or against a wall, can utilise space which would otherwise be wasted. They can also be designed to fit the space, for instance the cell can be a triangle in the corner of the building giving easy access to the forklift from the centre without disrupting other machinery around it.

“Cost was a major factor in how the Agristack range of palletisers was developed. This means that the average refurbished robot palletiser now has an installation value of £60,000 including bag handling solutions, which has a faster ROI than other products on the market. Robotics also hold their resale value better than other types of palletisers, for the reasons described above.”

Q: What about ancillary equipment, service and support?

A: “Bradley Engineering offers not only the sale and installation of robotic palletisers, but a full support package for all types of robot installation. This means that with a wealth of knowledge and spare parts at hand, any issue can be resolved quickly to get production running again. The company produces in house, conveyors, roller tables, presentation equipment and control panels in order to complete the automation process and integrate the robotic solution into your current machinery.”