New automatic grain moisture and temperature control system launches

9th February 2022

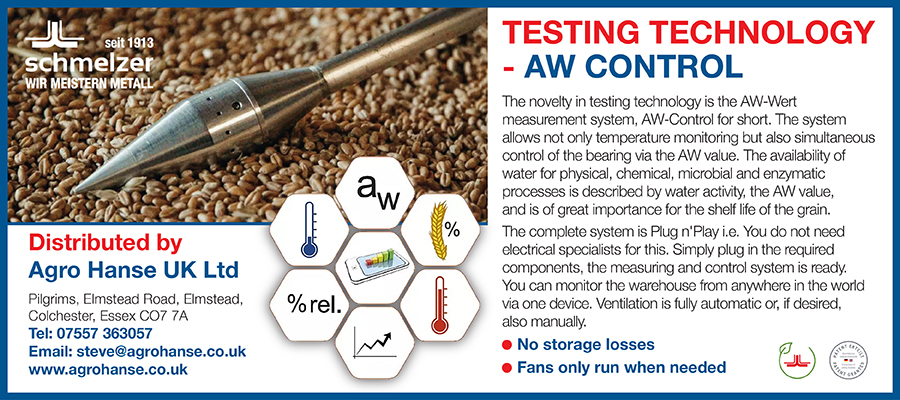

After five years of development, Ambros Schmelzer has launched the new AW Control System, available from exclusive UK partner, Agro Hanse UK.

“Water is not just water”, an eminent scientist specialising in grain storage once said. In this context, what he meant was, that moisture in grain can manifest itself in several ways… in the air surrounding the grain, on the grain surface and within the grain itself.

A new automatic grain moisture and temperature control system, recently launched by German grain conditioning specialists, Ambros Schmelzer, takes account of this and uses the term AW or ‘Water Activity’.

Professional grain store managers are already well aware of automatic systems for temperature control in grain, but this new system goes well beyond current industry standards, Steve Chapman of Agro Hanse says.

It is energy and labour efficient with accurate pinpointing of specific areas switching fans on and off as required. In addition to keeping close watch on external %RH, the AW Control System monitors and reacts to moisture and temperature, deep inside the grain profile.

And with carefully sited state-of-the-art sensors, the system can monitor temperature and moisture at 1m intervals up to 7m depth over long storage periods.

Data control boxes with wi-fi or LAN connection keep fans in direct contact with all sensor points and ensure data is retrieved and stored for long term traceability.

It is adaptable to suit any system of storage or ventilation, whether it’s flat storage, round silos, underfloor ventilation, pedestals or telescopic laterals.

Existing fans can be retro-fitted with the control box, or new Schmelzer fans are supplied AW-ready with a built-in control box.

Essex-based Agro Hanse UK, which has a global customer base, is the result of a long-term partnership between Steve Chapman and European manufacturers CanAGRO and Ambros Schmelzer, both of which have been long established in European agriculture.

Should you wish to see it working in practice, Schmelzer offers a facility to log-in to a test account where you can view an actual setup of the required components, which are installed at one of Schmelzer’s testing facilities.

For further information contact Steve Chapman or visit www.agrohanse.co.uk