Don’t discount delaying drilling

21st September 2020

With last autumn’s wet weather significantly impacting winter cereal crop establishment, many growers will be contemplating bringing this year’s drilling dates forward into late September or early October. ADAMA’s Bill Lankford therefore examines why this strategy goes against all best practice advice for controlling black-grass populations and explains why – alongside weed mapping, rotation planning, cultivation technique and herbicide programmes – delaying drilling is still one of the key tactics for beating black-grass.

With last autumn’s wet weather significantly impacting winter cereal crop establishment, many growers will be contemplating bringing this year’s drilling dates forward into late September or early October. ADAMA’s Bill Lankford therefore examines why this strategy goes against all best practice advice for controlling black-grass populations and explains why – alongside weed mapping, rotation planning, cultivation technique and herbicide programmes – delaying drilling is still one of the key tactics for beating black-grass.

The extent of the problem

With fewer herbicides to choose from, and resistance to some active ingredients on the rise, black-grass remains a significant problem in large parts of the UK, with the extent of the problem largely dependent on cultivation strategy, rotation, soil type, drainage and herbicide inputs. In the worst affected areas, it is commonly accepted that infestations will never be totally eradicated, but as long as adequate measures are put in place, black-grass populations can be managed down to an acceptable level.

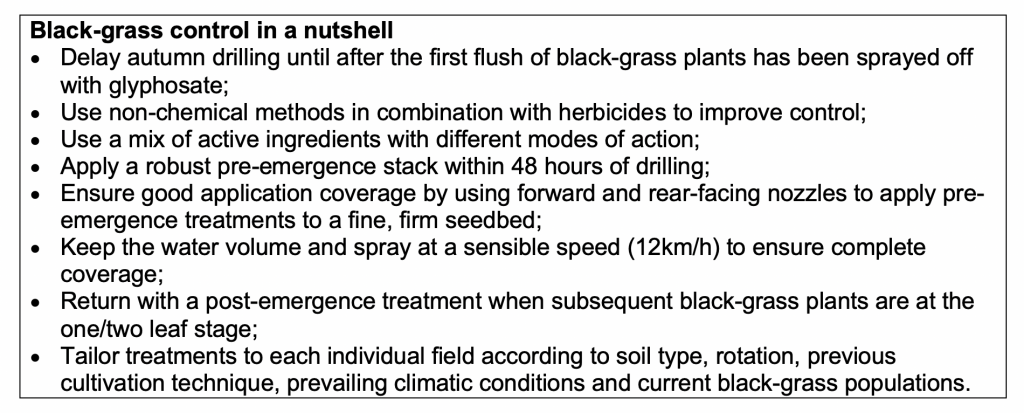

In addition to the use of a robust programme of herbicide applications – including pre-emergence and early post-emergence residual treatments – the key advice is to introduce more spring crops into the rotation and to delay the drilling of winter crops until mid-October or beyond. In addition, paying attention to details such as drilling badly infected fields last, reducing sprayer forward operating speeds and using appropriate spray nozzles to maximise coverage and reduce drift can all contribute to improved black-grass control.

The right herbicide for the job

In addition to selecting an herbicide based on the overall efficacy of its active ingredient(s), consideration should also be given to the ability of those compounds to remain effective in variable seedbed conditions.

The following factors should therefore be assessed ahead of and during the spraying season, with each treatment customised and adapted using a combination of active ingredients to suit the prevailing field conditions:

Water solubility: active ingredients with good water solubility ratings (such as chlorotoluron and flufenacet) will be taken up more easily in early, drier seedbeds (e.g. at pre-emergence and early post-emergence timings).

Half-life duration: active ingredients with an extended half-life duration (the time it takes for the active ingredient’s parent compound to degrade by 50%) will provide reliable residual activity for longer after application.

Customise and adapt

The message is clear: with variable and unpredictable weather patterns adding to the crop protection challenge, growers shouldn’t simply rely on those active ingredients they’ve used in the past. Instead, professional agronomic guidance should be taken to ensure the spray programme is viable for the current cropping conditions, and where necessary tailored by selecting those active ingredients which will provide the best level and longevity of protection in the prevailing climatic and soil conditions.

For example, Tower (chlorotoluron 250 g/l, pendimethalin 300 g/l & diflufenican 40 g/l) will ensure good uptake even in the driest conditions thanks to its CTU component and will also provide good longevity of efficacy thanks to its PDM and DFF components. Likewise, Herold (flufenacet 400g/l & diflufenican 200 g/l) will also provide good efficacy in dry conditions and also offers extended longevity. Alternatively, Anthem (pendimethalin 400 g/l) will provide good all-round protection and longevity in a wide range of conditions.

ADAMA UK’s Technical Specialist, Bill Lankford

Lessons learned

Despite the difficulties that last autumn’s wet conditions imposed on many growers, those that managed to get their crops drilled and treated with the appropriate residuals actually saw decent levels of black-grass control: thanks largely to the delayed drilling date and the fact there was plenty of soil moisture available to enable the residual herbicides to work efficiently.

Unfortunately, for some growers, the cold and wet start to the spring caused a backwards step in black-grass control, with crops tillering less and growing away too slowly to enable them to out-compete weeds. Contact herbicides were also less effective in the spring predominantly as a result of the wet conditions which prevented applications from being made at the optimum timing, or, in some cases, preventing applications from being put on at all.

Delaying drilling

As well as enabling the first flush of black-grass seedlings to be destroyed, delaying drilling can also improve the efficacy of pre-emergence herbicides which will be more effective when applied in damp soil conditions. Black-grass plants which emerge in later drilled crops also tend to be less competitive and may produce fewer seeds per plant.

Timing of drilling is therefore key in the fight against black-grass: waiting until as late as possible (from mid-October and into November for the best results) is the main advice, but this could make drilling conditions trickier: hence the recent rise in popularity of lighter/smaller seed drills which can still be used in wetter conditions.

Delaying drilling can also create difficulties in terms of managing later season workloads and can give the potential for yields to fall slightly – but, for some, these factors could be an acceptable price to pay for reducing the weed burden on severely infected land. For other, less affected areas, it may suffice to only push the drilling date back for the worst black-grass fields.